Syed M. A. Bukhari

Department of Mechanical Engineering, Faculty of Engineering and Technology, Bahauddin Zakariya University, Multan, Pakistan.

Syed A. R. Gardezi

Department of Mechanical Engineering, Faculty of Engineering and Technology, Bahauddin Zakariya University, Multan, Pakistan

Naveed Husnain

Department of Mechanical Engineering, Faculty of Engineering and Technology, Bahauddin Zakariya University, Multan, Pakistan

Rauf Ahmad

Department of Mechanical Engineering, Faculty of Engineering and Technology, Bahauddin Zakariya University, Multan, Pakistan

Muhammad F. Zaman

Department of Mechanical Engineering, Faculty of Engineering and Technology, Bahauddin Zakariya University, Multan, Pakistan

Rashida Qurashi

Government Graduate College for Women, Makhdoom Rasheed, Multan, Pakistan

Nosheen Baloch

Department of Building Architectural Engineering, Faculty of Engineering and Technology, Bahauddin Zakariya University, Multan, Pakistan

DOI: https://doi.org/10.14456/apst.2025.10

Keywords: Corrosion potential Sacrificial anodes Cathodic protection COMSOL Multiphysics CP modeling Y pipes

Abstract

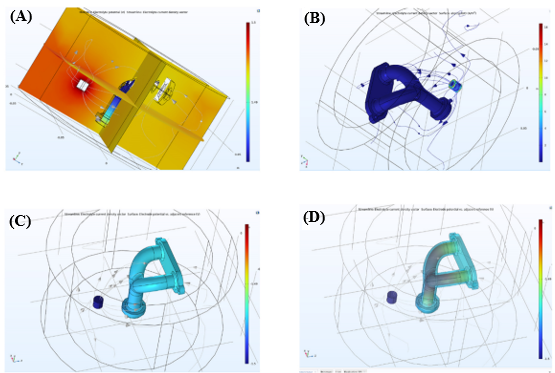

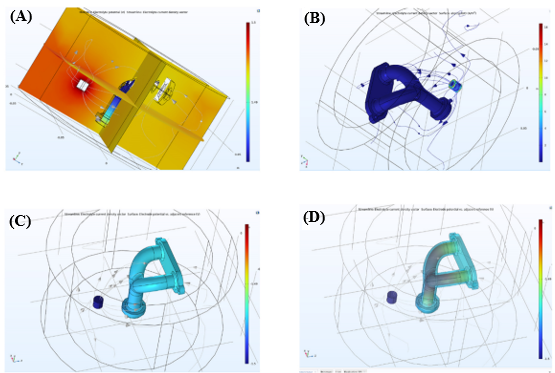

Pipelines under the sea are at great risk of corrosion due to highly conductive seawater acting as a strong electrolyte. Current study is aimed to resolve this issue of corrosion of pipes in seawater. This computational study exhibits the modeling and simulation of corrosion protection of a bent y-pipe using the sacrificial anode cathodic protection method. Steel is selected as pipe material and the pipe is studied under seawater conditions. A high-potential cylindrical Magnesium anode is selected to study its effect on corrosion prevention of the Y-pipe. The size of the anode is varied to study its effect on corrosion protection. COMSOL Multiphysics is used for the computational study of cathodic protection. The results indicated that cathodic protection can be a good choice for the protection of pipelines under the sea. However, a proper design and size of the anode must be incorporated for effective corrosion protection. Decreasing the radius of the cylindrical anode reduced the protection of the Y pipe as 0.2 mm radius anode exhibits -1.471 V pipe potential vs Ag/AgCl which is -1.498 V for anode size of 15 mm. Areas having bends tend to have more corrosion potential due to stress concentration and are at a greater risk of corrosion. Moreover, the model also indicated that apart from cathodic protection, corrosion inhibitors are also required inside the pipelines to prevent internal corrosion.

How to Cite

Bukhari, S. M. A. ., Gardezi, S. A. R. ., Husnain, N., Ahmad, R. ., Zaman, M. F. ., Qurashi, R. ., & Baloch, N. . (2025). Modelling and simulation of cathodic protection using magnesium sacrificial anode for steel Bent-Y-Pipe in seawater environment. Asia-Pacific Journal of Science and Technology, 30(01), APST–30. https://doi.org/10.14456/apst.2025.10

References

Masood Arif Bukhari S, Husnain N, Arsalan Siddiqui F, Tuoqeer Anwar M, Abbas Khosa A, Imran M, et al. Effect of laser surface remelting on Microstructure, mechanical properties and tribological properties of metals and alloys: A review. Opt Laser Technol. 2023;165:109588.

Bukhari SMA, Naveed A, Husnain N, Siddiqui FA, Zaman MF, Ahmad A, et al. Computational study of mechanical behavior of Ti6Al4V-Coated and Aluminium-Coated 316L stainless steel alloy under linear and cyclic loading. Tech J. 2023;28(3):12-24.

Tamalmani K, Husin H. Review on corrosion inhibitors for oil and gas corrosion issues. Appl Sci. 2020;10(10): 3389.

Lambert P. 6 – Sustainability of metals and alloys in construction. In: Khatib JM, editor. Sustainability of Construction Materials. 2ed ed. Woodhead Publishing; 2016. p. 105-128.

Zhang X. Galvanic corrosion. Uhlig’s Corrosion Handbook. 2011;51:123.

Angst UM. A critical review of the science and engineering of cathodic protection of steel in soil and concrete. Corrosion. 2019;75(12):1420-1433.

Cathodic protection design. Recommended practice DNV-RP-B401. Hovik: Det Norske Veritas. 2010.

Wyatt BS. Practical application of cathodic protection. In: Shreir’s Corrosion. Elsevier; 2010. p. 2801–2832.

Krishnan N, Kamde DK, Doosa Veedu Z, Pillai RG, Shah D, Velayudham R. Long-term performance and life-cycle-cost benefits of cathodic protection of concrete structures using galvanic anodes. J Build Eng. 2021;42:102467.

Abootalebi O, Kermanpur A, Shishesaz MR, Golozar MA. Optimizing the electrode position in sacrificial anode cathodic protection systems using boundary element method. Corros Sci. 2010;52(3):678-87.

Roberge PR. Handbook of Corrosion Engineering. 3rd ed. New York: McGraw-Hill Education; 2019.

Fu AQ, Cheng YF. Effect of alternating current on corrosion and effectiveness of cathodic protection of pipelines. Can Metall Q. 2012;51(1):81-90.

Xu LY, Su X, Cheng YF. Effect of alternating current on cathodic protection on pipelines. Corros Sci. 2013;66:263-8.

Kuang D, Cheng YF. Effects of alternating current interference on cathodic protection potential and its effectiveness for corrosion protection of pipelines. Corros Eng Sci Technol. 2017;52(1):22-28.

Ormellese M, Beretta S, Brugnetti F, Brenna A. Effects of non-stationary stray current on carbon steel buried pipelines under cathodic protection. Constr Build Mater. 2021;281:122645.

Zhang L, Liang Z, Li S. Effect of current density on the cathodic protection efficiency and mechanical properties of pre-stressed high-strength steel wires for stay cable. Constr Build Mater. 2022;314:125671.

Shaalan EM, Mostafa MA, Hamza AS, Al-Gabalawy M. Cathodic Protection Performance Improvement of Metallic Pipelines based on Different DC Compensation Methods. Electr Power Syst Res. 2022;210:108064.

Xu LY, Cheng YF. Experimental and numerical studies of effectiveness of cathodic protection at corrosion defects on pipelines. Corros Sci. 2014;78:162-171.

Kuang D, Cheng YF. Study of cathodic protection shielding under coating disbondment on pipelines. Corros Sci. 2015;99:249-257.

Zaman MF, Bukhari SMA, Husnain N, Abbas Z, Ayyub A, Najmi MF, et al. Effect of zirconium carbide coating on thermal behavior of heavy duty V12 diesel engine using finite element method. Eng Res Express. 2024;6(2):025549.

Oghli HM, Akhbari M, Kalaki A, Eskandarzade M. Design and analysis of the cathodic protection system of oil and gas pipelines, using distributed equivalent circuit model. J Nat Gas Eng. 2020;84:103701.

Chung N-T, Hong M-S, Kim J-G. Optimizing the required cathodic protection current for pre-buried pipelines using electrochemical acceleration methods. Materials. 2021;14(3):579.

Lorenzi S, Pastore T, Bellezze T, Fratesi R. Cathodic protection modelling of a propeller shaft. Corros Sci. 2016;108:36-46.

Bellezze T, Fratesi R, Roventi G. Cathodic protection of a ship propeller shaftby impressed current anodes. Metall. Ital. 2014;106(7):3-10.

Ghazi AR, Khan HI, Farooq M, Jahangir S, Anwar MT. Effect of temperature and medium environment on corrosion fatigue behavior of Inconel 625. Mater Corros. 2023;74(7):1030-1038.

Chen S, Hartt W. Deepwater Cathodic Protection: Part 1Laboratory Simulation Experiments. Corrosion. 2002;58(01):38-48.

Gadala IM, Abdel Wahab M, Alfantazi A. Numerical simulations of soil physicochemistry and aeration influences on the external corrosion and cathodic protection design of buried pipeline steels. Mater Des. 2016;97:287-299.

Vasilescu M-V, Panaitescu M, Panaitescu F-V. Marine impressed current cathodic protection system. Hidraulica. 2019(4):45-62.

Liu D, Zhang J, Wang X. Numerical simulation of submarine shaft-rate electric field based on COMSOL finite element. In: Patnaik S, Wang J, Yu, Z, Dey, N. editords. Recent developments in mechatronics and intelligent robotics. ICMIR 2019. Advances in intelligent systems and computing, vol. 1060. Singapore: Springer; 2020. p. 107-116.

Kalovelonis DT, Rodopoulos DC, Gortsas TV, Polyzos D, Tsinopoulos SV. Cathodic protection of a container ship using a detailed BEM model. J mar sci eng. 2020;8(5):359.

Husnain N, Siddiqui FA, Ahmad R, Bukhari SMA, Nasir I, Shafi MF, et al. Experimental and computational study of the most influential parameters of a lab-scale forced draft cooling tower by considering different number of packing ribs. Tech J. 2022;27(04):20-27.

Naveed A, Bukhari SMA, Husnain N, Baloch N, Noor S, Ahmad W, et al. Structural integrity and cost analysis of a connecting rod for articulated robotic arm using various stainless steel and aluminium alloys. Tech J. 2024;29(2):24-34.

Published:

License

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.