Russamee Junkraweekoon

Department of Sanitary Engineering, Faculty of Public Health, Mahidol University, Bangkok, Thailand

Suphaphat Kwonpongsagoon

Department of Sanitary Engineering, Faculty of Public Health, Mahidol University, Bangkok, Thailand

Kanokwan Kingphadung

Department of Food Technology, Faculty of Engineering and Industrial Technology, Silpakorn University, Thailand

DOI: https://doi.org/10.14456/apst.2025.13

Keywords: Sustainable Industry Sugarcane Sugar Waste management Cost Benefit Benefit-cost ratio (BCR)

Abstract

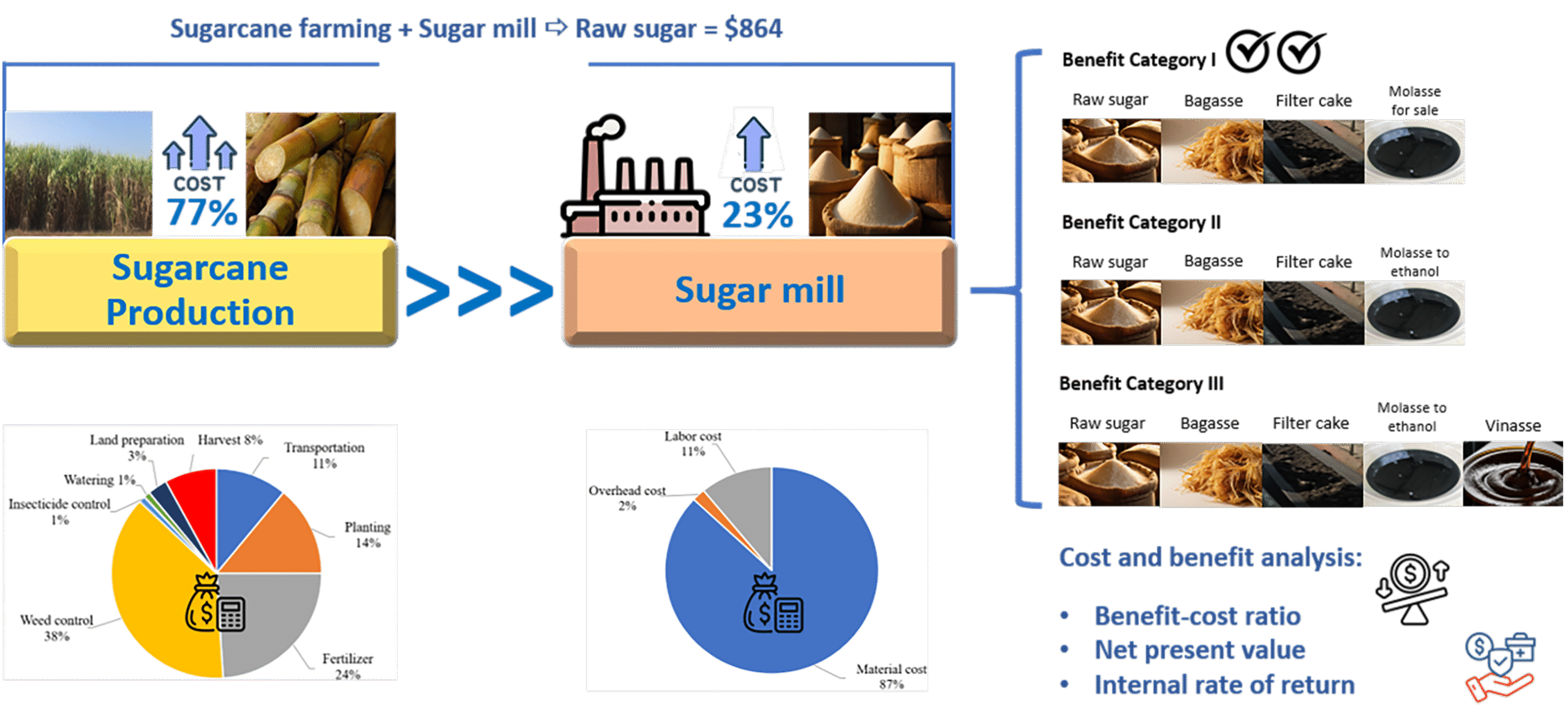

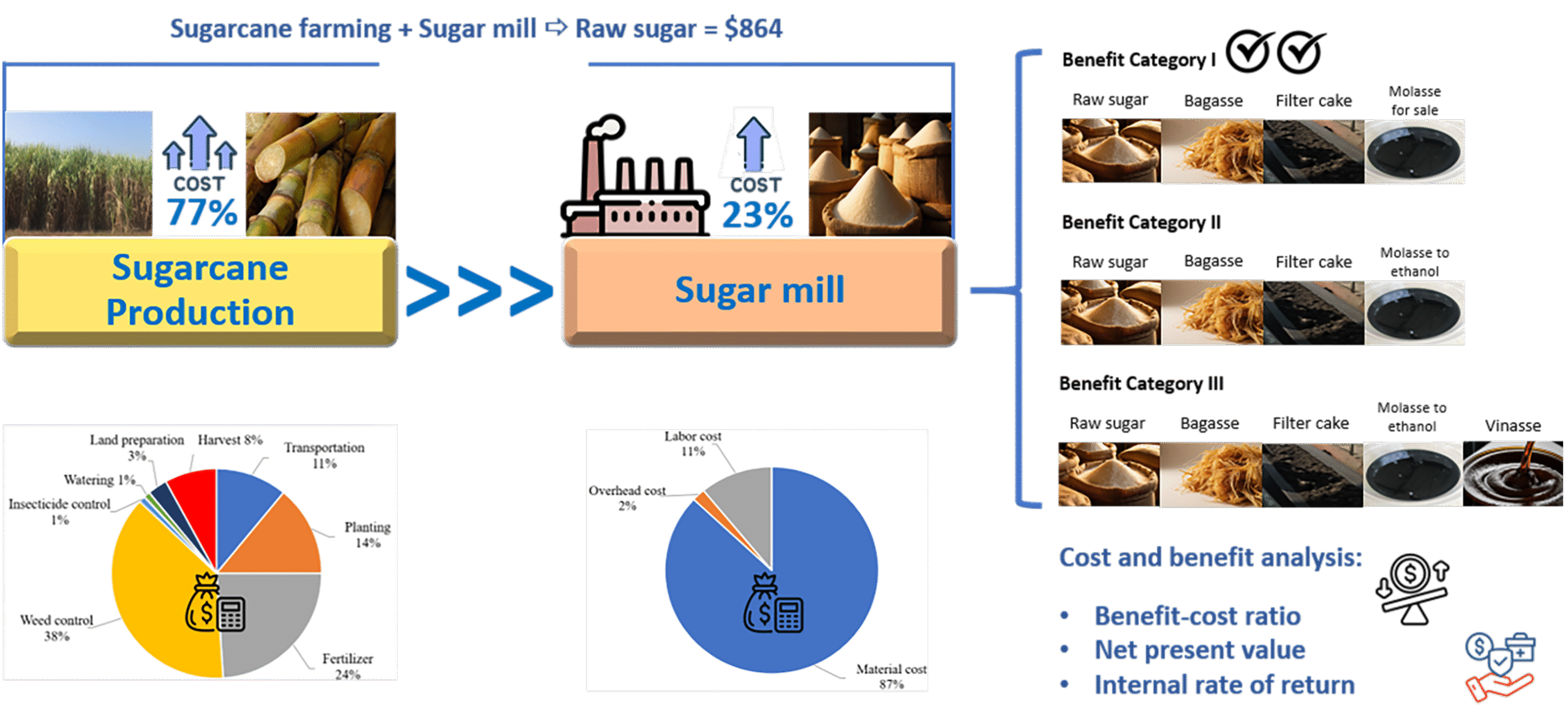

This study analyzes the financial costs and benefits associated with various agricultural practices, industrial processes, products, byproducts and waste management, starting from sugarcane plantations to the end users of products and byproducts of sugar processing. The field survey and data collection were conducted using face-to-face interviews during the 2020/21 crop year. The findings indicate that the total variable sugar production cost of the entire industry is 864 USD per ton of raw sugar crystal, with 77% coming from sugarcane production and 23% from the sugar production process. The highest cost of sugarcane production was in the weed control process, accounting for 38%, followed by fertilizer application, planting, sugarcane transported to the mill, harvesting, and others (land preparation, insecticide control and crop maintenance) at 24, 14, 11, 8 and 5%, respectively. The findings of Benefit-Cost Ratio, Net Present Value, and Internal Rate of Return analysis indicate that for the process of cane production and the entire sugar industry, the benefit category I, by using three main byproducts: 1) selling molasses for other uses or production; 2) selling filter cake as fertilizer, and 3) using bagasse as fuel to generate electricity, is the most economically feasible. Although all profits are returned only to the sugar factory, using these byproducts and wastes can bring enormous environmental benefits. Moving towards a sustainable sugar industry in Thailand, a need exists to improve sugarcane production by reducing production costs, e.g., reducing inputs such as chemicals, fertilizer and fuels, and increasing sugarcane productivity.

How to Cite

Junkraweekoon, R. ., Kwonpongsagoon, S., & Kingphadung, K. (2025). Towards sustainable sugar industry in Thailand: Cost and benefit analysis. Asia-Pacific Journal of Science and Technology, 30(01), APST–30. https://doi.org/10.14456/apst.2025.13

References

Photchanaprasert N, Patoomnakul A, Suchato R, Tanrattanaphong B. Thailand’s sugar industry’s global value chain competitiveness and upgrading strategy. Proceedings of the 2nd international conference on cane and sugar 2023; 5-7 July 2023; Asawin Grand Convention Hotel. Bangkok, Thailand: Thailand Society of Sugar Cane Technologists (TSSCT) Press; 2023. p. 213-216.

Jarumaneeroj P, Dusadeerungsikul PO, Chotivanich T. and Akkerman R. A multi-objective modeling approach to harvesting resource scheduling: decision support for a more sustainable Thai sugar industry. Comput Ind Eng. 2021;162:107694.

Sriroth K, Vanichsriratana W, Sunthornvarabhas J. The current status of sugar industry and by-products in Thailand. Sugar Tech. 2016;18(6):576-582.

Sukyai P, Yingkamhaeng N, Lam NT, Tangsatianpan V, Watcharinrat C, Vanitjinda G, et al. Research and development prospects for sugarcane and sugar industry in Thailand. Sugar Tech. 2016;18(6):583-587.

Chunhawong K, Chaisan T, Rungmekarat S, Khotavivattana S. Sugar industry and utilization of its by-products in Thailand: an overview. Sugar Tech. 2018;20(2):111-115.

Solomon S, Swapna M, Xuan VT, Mon YY. Development of sugar industry in ASEAN countries. Sugar Tech. 2016;18(6):559-575.

Manivong P, Bourgois E. White Paper: Thai sugarcane sector and sustainability. FairAgora Asia Co Ltd; 2023.

Lee H, Sohn YJ, Jeon S, Yang H, Son J, Kim YJ, and Park SJ. Sugarcane wastes as microbial feedstocks: A review of the biorefinery framework from resource recovery to production of value-added products. Bioresour Technol. 2023;376:1-13.

Celiktopuz E, Kapur B, Sarıdas MA, Güney Oİ, Aksoy F. Yield quality and physiological variation of strawberry in response to irrigation regimes and exogenous proline with a cost benefit analysis. Plant Physiol Biochem. 2023;195:238-246.

Mkindi AG, Coe R, Stevenson PC, Ndakidemi PA, Belmain SR. Qualitative cost-benefit analysis of using pesticidal plants in smallholder crop protection. Agriculture. 2021;11:1-13.

Amatayakul P, Chomtha T. Agricultural meteorology to know for Suphan Buri. Meteorological Development Bureau, Ministry of Digital Economy and Society, Thailand; 2015.

Kingphadung K, Kurdkaew P, Siriwongwilaichat P, Kwonpongsagoon S. Comparison of performance and economic efficiency for greenhouse solar versus hot air drying: a case of crispy mango production. Processes. 2022;10(2):311.

Phusavat K. Productivity management in an organization: measurement and analysis. ToKnowPress Monographs: ToKnowPress; 2013.

Tangen S. Performance measurement: from philosophy to practice. Int J Product Perform Manag. 2004;53(8):726-737.

Bank of Thailand (BOT). Currency exchange rates based on daily reference rates, Thursday April 12, 2023, Thailand [Internet]. 2023 [cited 2023 April 12]. Available from https://www.bot.or.th/th/statistics/exchange-rate.html

Pisuttinusart C, Jatuporn C, Suvanvihok V, Seerasarn N. Forecasting the import demand for chemical fertilizer in Thailand. The EUrASEANs. 2022;3(34):61-70.

Athipanyakul T. Sugarcane production efficiency of small-scale farmers in Thailand. Int Sugar J. 2018;120(1434): 470-475.

Parsaee M, Kiania MKD, Karimib K. A review of biogas production from sugarcane vinasse. Biomass Bioenergy. 2019;122:117-125.

Pereira IZ, Santos IFS, Barros RM, Silva HLC, Filho GLT, Silva APM. Vinasse biogas energy and economic analysis in the state of Sao Paulo, Brazil. J Clean Prod. 2020;260:1-11.

Neto JVS, Gallo WLR, Nourb EAA. Production and use of biogas from vinasse: implications for the energy balance and GHG emissions of sugar cane ethanol in the Brazilian context. Environ Prog Sustain Energy. 2020;39(1):13226.

Santana Jr. AE, Duda RM, Oliveira RA. Improving the energy balance of ethanol industry with methane production from vinasse and molasses in two-stage anaerobic reactors. J Clean Prod. 2019;238:1-11.

Ministry of Labour (MOL). The minimum wage and enforcement (since 1973 – present) [Internet]. Bangkok: Ministry of Labour. 2023. [cited 2023 May 21]. Available from https://www.mol.go.th/en/minimum-wage.

Energy Policy Planning Office (EPPO). Report of fuel price situation [Internet]. Bangkok: Ministry of Energy 2023. [cited 2023 May 28]. Available from https://www.eppo.go.th/epposite/index.php/th/petroleum/price/oil-price?orders[publishUp]=publishUp&issearch=1.

Sureeyatanapas P, Pancharoen D, Saengprachatanarug K. Finding the sweet spot in industry 4.0 transformation: an exploration of the drivers, challenges, and readiness of the Thai sugar industry. Benchmarking. 2024;31(10):3965-3996.

Published:

License

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.