Thawanrat Sumrit

Department of Food Engineering, Faculty of Food and Agricultural Technology, Pibulsongkram Rajabhat University, Phitsanulok 65000, Thailand

Surintraporn Swaeng-ngam

Department of Food Engineering, Faculty of Food and Agricultural Technology, Pibulsongkram Rajabhat University, Phitsanulok 65000, Thailand

Patcharaporn Inrirai

Department of Food Engineering, Faculty of Food and Agricultural Technology, Pibulsongkram Rajabhat University, Phitsanulok 65000, Thailand

Voraluck Suriwong

Department of Food Engineering, Faculty of Food and Agricultural Technology, Pibulsongkram Rajabhat University, Phitsanulok 65000, Thailand

Tanakorn Jantarasricha

Department of Production Engineering Technology, Faculty of Industrial Technology, Pibulsongkram Rajabhat University, Phitsanulok 65000, Thailand

DOI: https://doi.org/10.14456/apst.2025.76

Keywords: De-oiling Enoki mushroom Machine Vertical centrifugation Weight yield

Abstract

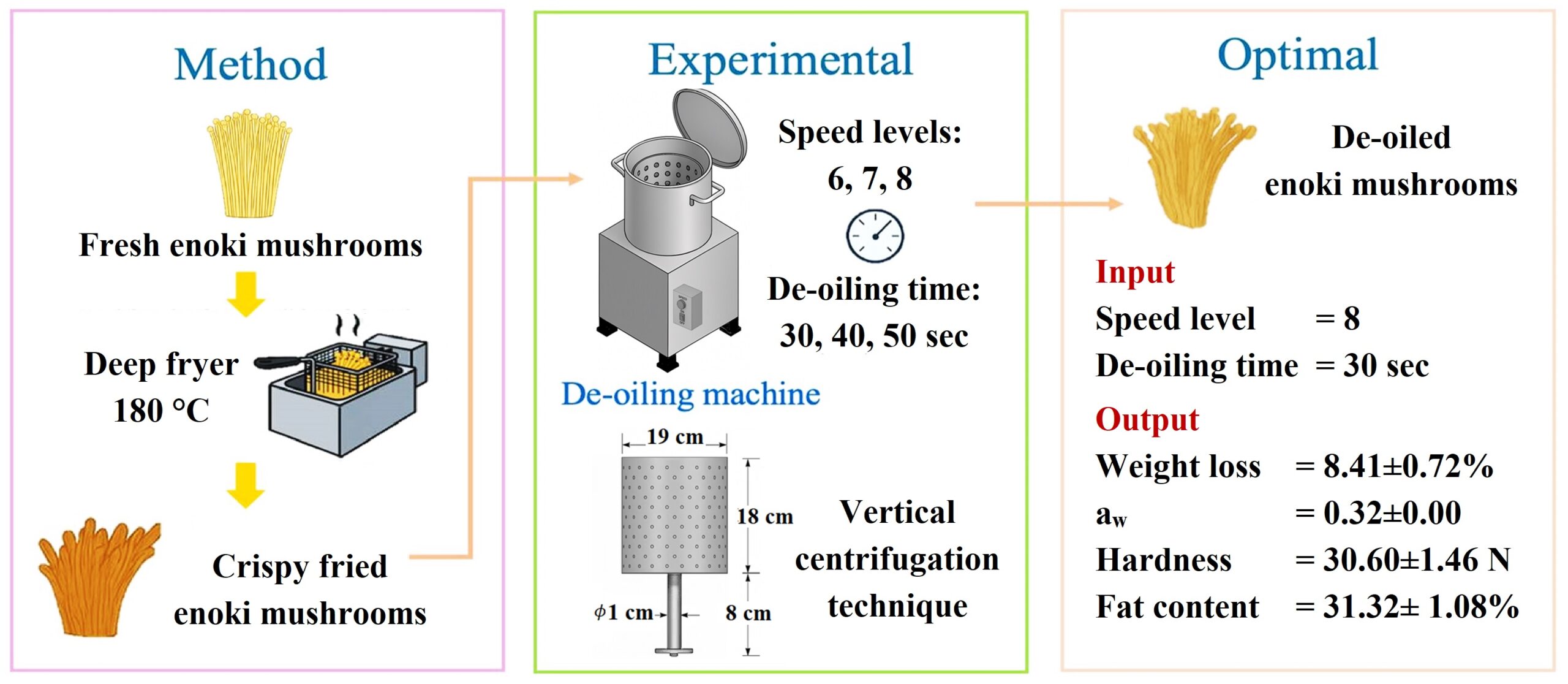

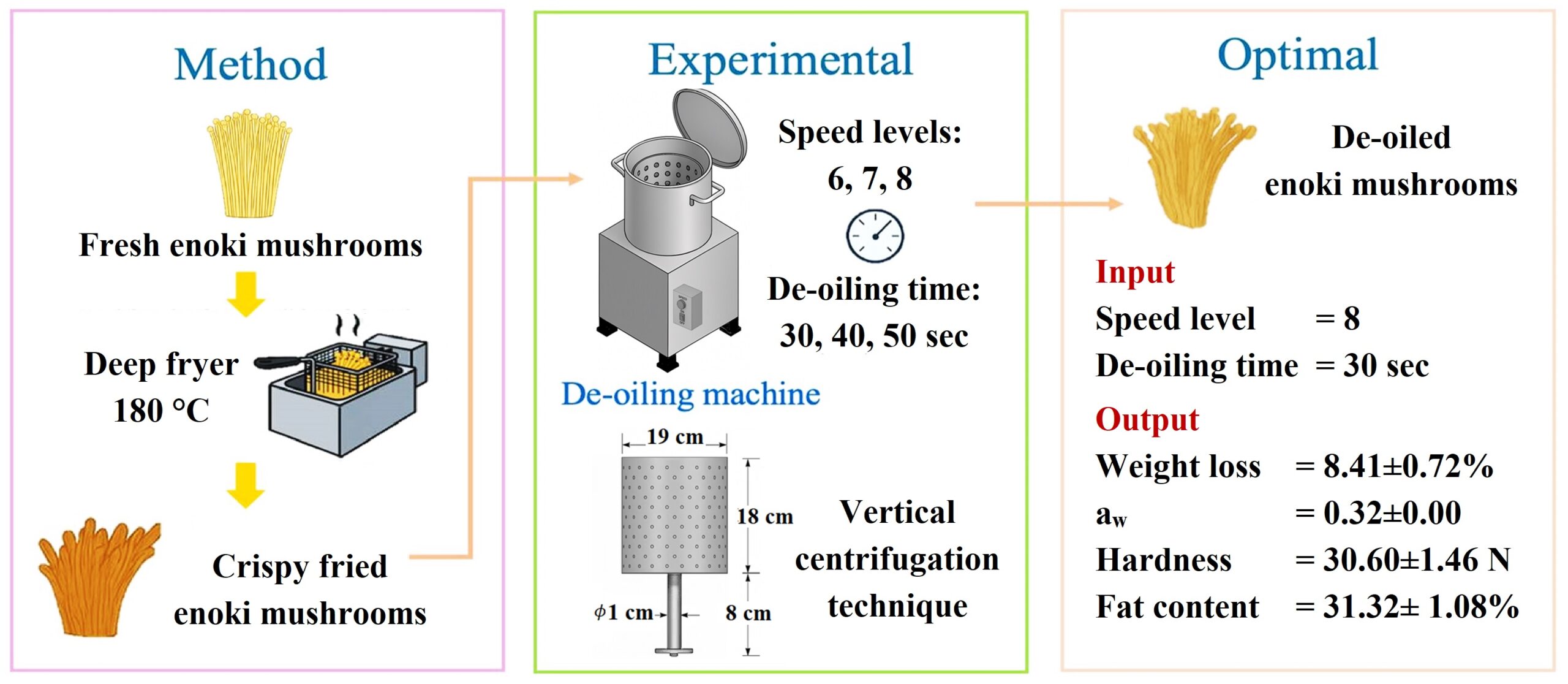

The aim of this research was to develop a de-oiling machine and evaluate its efficiency when making crispy fried enoki mushrooms in terms of reducing residual oil in the product after the frying process. This machine had five essential components: vertical centrifugation, an external tank, a motor unit, oil drainage, and a speed adjustment mechanism. After the frying process, the crispy enoki mushrooms had an average weight of 150 g. The adjustment of the de-oiling speed levels was examined using three different speeds: 6, 7, and 8, while the de-oiling durations were set at 30, 40, and 50 sec. The results revealed that the use of different operating conditions affected the removal of oil. The de-oiling process, conducted at speed level 8 for a duration of 30 sec, resulted in a weight loss of 8.41±0.72% after the oil removal. The aw value obtained was 0.32±0.00, while the hardness value was 30.60±1.46 N. Additionally, the fat content was determined to be 31.32± 1.08%. This operation enabled improved textural qualities compared to other conditions. Compared to the control sample, the samples with lower fat content exhibited increased crispiness. Meanwhile, the control sample had a fat content of 45.05±0.28% and a hardness of 28.36±0.21 N. The efficiency of oil removal from crispy fried enoki mushrooms was enhanced using this developed de-oiling machinery, which ensures that the texture and flavor of these mushrooms are preserved after the frying process.

How to Cite

Sumrit, T., Swaeng-ngam, S., Inrirai, P., Suriwong, V., & Jantarasricha, T. (2025). Application of a vertical centrifugation technique to develop a de-oiling machine for crispy fried enoki mushrooms. Asia-Pacific Journal of Science and Technology, 30(05), APST–30. https://doi.org/10.14456/apst.2025.76

References

Wunjuntuk K, Ahmad M, Techakriengkrai T, Chunhom R, Jaraspermsuk E, Chaisri A, et al. Proximate composition, dietary fibre, beta-glucan content, and inhibition of key enzymes linked to diabetes and obesity in cultivated and wild mushrooms. J Food Compos Anal. 2022; 105:104-226.

Ikeda S, Yamauchi M, Watari T, Hatamoto M, Yamada M, Maki S, et al. Development of enokitake (Flammulina velutipes) mushroom cultivation technology using spent mushroom substrate anaerobic digestion residue. Environ Technol Innov. 2021; 24:1020-1046.

Fukushima M, Ohashi T, Fujiwara Y, Sonoyama K, Nakano M. Cholesterol-lowering effects of maitake (Grifola frondosa) fiber, shiitake (Lentinus edodes) fiber, and enokitake (Flammulina velutipes) fiber in rats. Exp Biol Med. 2001;226(8):758–765.

Yeh MY, Ko WC, Lin LY. Hypolipidemic and antioxidant activity of enoki mushrooms (Flammulina velutipes). Biomed Res Int. 2014;2014(1):352-385.

Navarro-Simarro P, Gómez-Gómez L, Ahrazem O, Rubio-Moraga Á. Food and human health applications of edible mushroom by-products. New Biotechnol. 2024; 81:43–56.

Liu Y, Tian J, Zhang T, Fan L. Effects of frying temperature and pore profile on the oil absorption behavior of fried potato chips. Food Chem. 2021; 345:128832.

Yang D, Wu G, Li P, Zhang H, Qi X. Comparative analysis of the oil absorption behavior and microstructural changes of fresh and pre-frozen potato strips during frying via MRI, SEM, and XRD. Food Res Int. 2019; 122:295–302.

Durán M, Pedreschi F, Moyano P, Troncoso E. Oil partition in pre-treated potato slices during frying and cooling. J Food Eng. 2007;81(1):257–265.

Blumenthal MM, Stier RF. Optimization of deep-fat frying operations. Trends Food Sci Technol. 1991; 2:144–148.

Patil RS, Waghmare J, Annapure U. Comparative assessment of the frying performance of palm olein and sunflower oil during deep-fat frying of Indian battered food products. J Agric Food Res. 2023; 14:1007-1078.

Choe E, Min DB. Chemistry of deep‐fat frying oils. J Food Sci. 2007;72(5): R77–86.

Al Faruq A, Khatun MHA, Azam SR, Sarker MSH, Mahomud MS, Jin X. Recent advances in frying processes for plant-based foods. Food Chem Adv. 2022; 1:100-186.

Van Vliet T, Visser JE, Luyten H. On the mechanism by which oil uptake decreases crispy/crunchy behaviour of fried products. Food Res Int. 2007;40(9):1122–1128.

Da Silva PF, Moreira RG. Vacuum frying of high-quality fruit and vegetable-based snacks. LWT-Food Sci Technol. 2008;41(10):1758–1767.

Dehghannya J, Ngadi M. Recent advances in microstructure characterization of fried foods: Different frying techniques and process modeling. Trends Food Sci Technol. 2021; 116:786–801.

Moreira RG, Da Silva PF, Gomes C. The effect of a de-oiling mechanism on the production of high-quality vacuum fried potato chips. J Food Eng. 2009;92(3):297–304.

Kim T, Moreira RG. De‐oiling and pretreatment for high‐quality potato chips. J Food Process Eng. 2013;36(3):267–275.

Pedreschi F, Kaack K, Granby K. Colour changes and acrylamide formation in fried potato slices. LWT-Food Sci Technol. 2005;38(5):499–506.

Bordin K, Kunitake MT, Aracava KK, Trindade MA. Changes in food caused by deep fat frying – A review. Arch Latinoam Nutr. 2013;63(1):90–98.

Dangal S, Thapa S, Thapa S, Shrestha AK. Review on deep-fat fried foods: chemical and physical changes, health implications, and mitigation strategies. Eur Food Res Technol. 2024;250(1):11–29.

Bhuiyan MHR, Ngadi M. Post-fry oil distribution in batter coated fried foods. LWT. 2024; 194:115819.

Devi S, Zhang M, Ju R, Mujumdar AS. Co-influence of ultrasound and microwave in vacuum frying on the frying kinetics and nutrient retention properties of mushroom chips. Dry Technol. 2019;38(15):2102–2111.

Pedreschi F, Leon J, Mery D, Moyano P, Pedreschi R, Kaack K, et al. Colour development and acrylamide content of pre-dried potato chips. J Food Eng. 2007;79(3):786–793.

Wang QL, Yang Q, Kong XP, Chen HQ. The addition of resistant starch and protein to the batter reduces oil uptake and improves the quality of the fried batter-coated nuts. Food Chem. 2024; 438:137992.

Liu Y, Tian J, Hu B, Yu P, Fan L. Relationship between crust characteristics and oil uptake of potato strips with hot-air pre-drying during frying process. Food Chem. 2021; 360:130-145.

Omidiran AT, Odukoya OJ, Akinbule OO, Sobukola OP. Effect of microwave-assisted pre-drying and deep-fat-frying conditions on some quality attributes of orange fleshed sweetpotato chips. Food Chem Adv. 2023; 3:1005-1034.

Cruz G, Cruz-Tirado JP, Delgado K, Guzman Y, Castro F, Rojas ML, et al. Impact of pre-drying and frying time on physical properties and sensorial acceptability of fried potato chips. J Food Sci Technol. 2018; 55:138–144.

Gomide AI, Monteiro RL, Laurindo JB. Impact of the power density on the physical properties, starch structure, and acceptability of oil-free potato chips dehydrated by microwave vacuum drying. LWT. 2022; 155:112917.

Vitrac O, Trystram G, Raoult‐Wack AL. Deep‐fat frying of food: Heat and mass transfer, transformations and reactions inside the frying material. Eur J Lipid Sci Technol. 2000;102(8–9):529–538.

Achir N, Kara W, Chipeaux C, Trezzani I, Cuvelier ME. Effect of energy transfer conditions on the chemical degradation of frying oil. Eur J Lipid Sci Technol. 2006;108(12):999–1006.

Ziaiifar AM, Achir N, Courtois F, Trezzani I, Trystram G. Review of mechanisms, conditions, and factors involved in the oil uptake phenomenon during the deep‐fat frying process. Int J Food Sci Technol. 2008;43(8):1410–1423.

Lin H-TV, Hou P-H, Sung W-C. Kinetics of oil absorption and moisture loss during deep-frying of pork skin with different thickness. Foods. 2021; 10:3029.

Mahmud N, Islam J, Oyom K, Adrah K, Adegoke SC, Tahergorabi R. A review of different frying oils and oleogels as alternative frying media for fat-uptake reduction in deep-fat fried foods. Heliyon. 2023;9(11): e21500.

Published:

License

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.