Natcharee Jirukkakul

Food Technology and Innovation Program, Applied Science Department, Interdisciplinary Studied Faculty, Khon Kaen University, Nong Khai Campus, Nong Khai, 43000 Thailand https://orcid.org/0000-0001-5653-0877

Bung-orn Hemung

Food Technology and Innovation Program, Applied Science Department, Interdisciplinary Studied Faculty, Khon Kaen University, Nong Khai Campus, Nong Khai, 43000 Thailand

Jaruvan Suebsuntorn

Food Technology and Innovation Program, Applied Science Department, Interdisciplinary Studied Faculty, Khon Kaen University, Nong Khai Campus, Nong Khai, 43000 Thailand

DOI: https://doi.org/10.14456/apst.2025.48

Keywords: Carboxymethyl cellulose Film Gelatin Pineapple core

Abstract

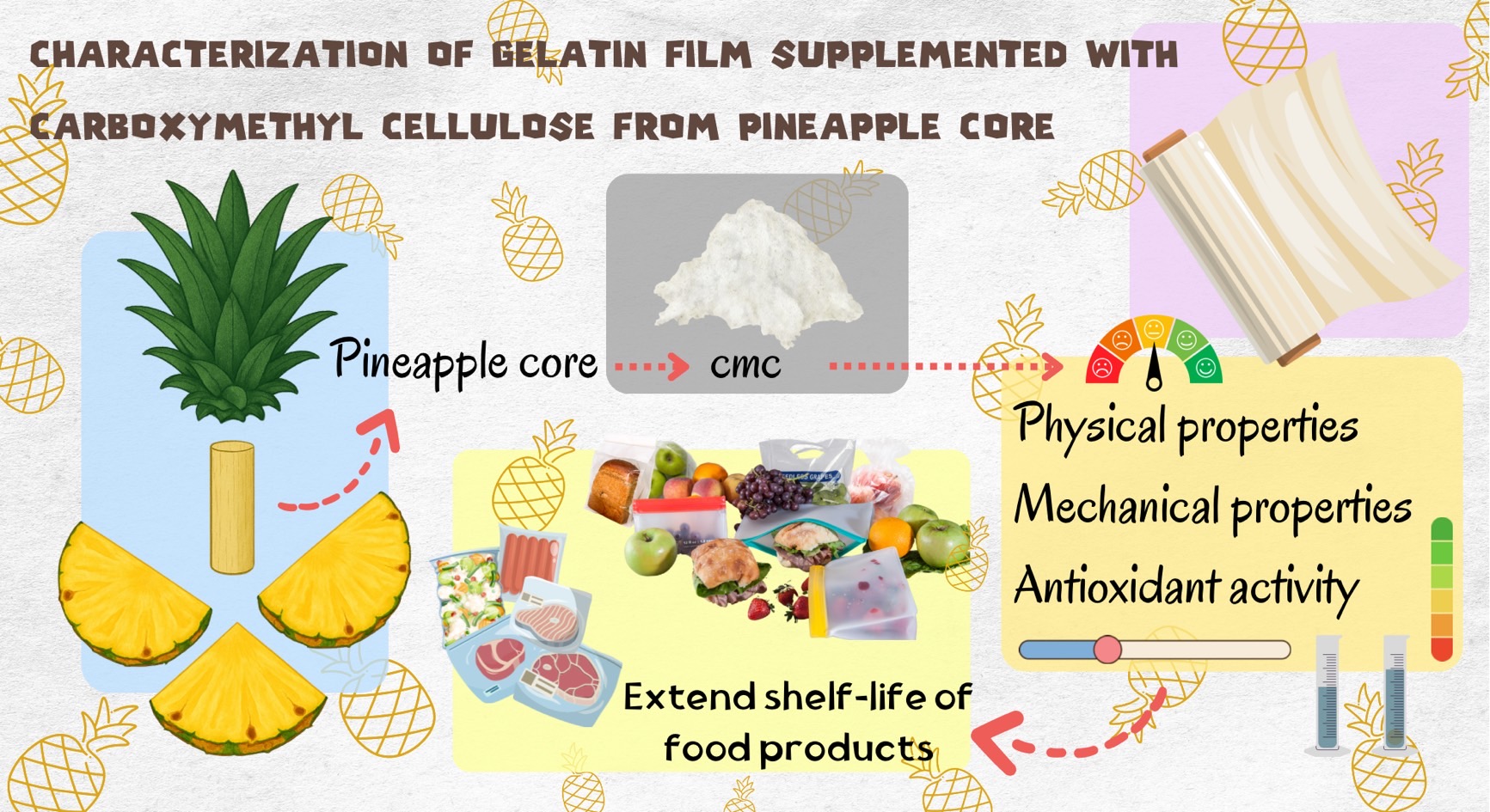

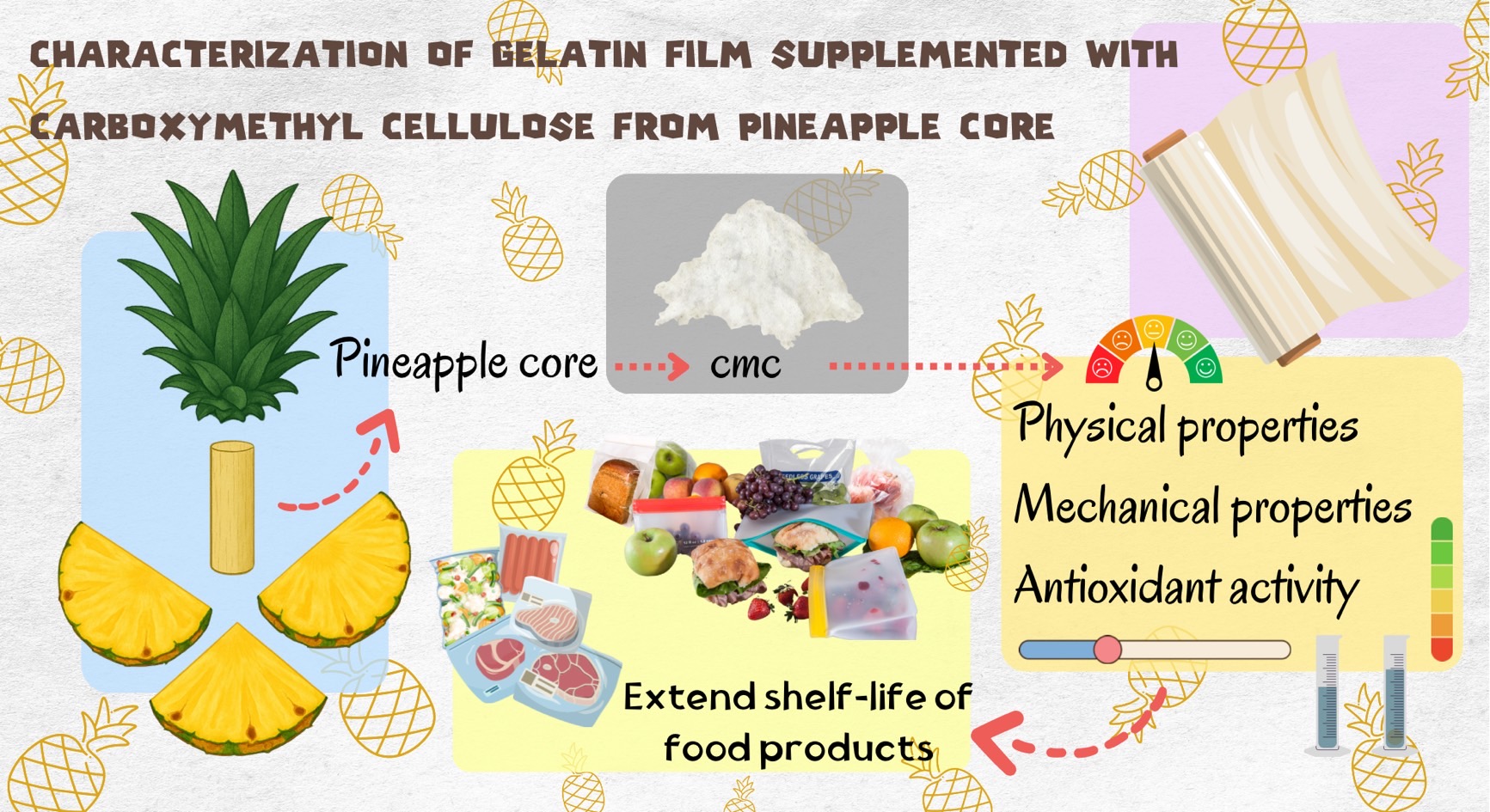

Pineapple (Ananus comosus) cores, waste from pineapple processing, contain cellulose and exhibiting a potential for food packaging. The edible film made from gelatin and carboxymethyl cellulose (CMC) synthesized from cellulose extracted from pineapple core showed a light-yellow color and smooth surface. They had the same moisture content, morphology and tensile strength as film from gelatin with commercial CMC. The solubility, thickness, water vapor permeability, and antioxidant activity were also similar. Thus, CMC from pineapple core has the potential for edible film applications which was evaluated compared to commercial CMC.

How to Cite

Jirukkakul, N., Hemung, B.- orn, & Suebsuntorn, J. (2025). Characterization of gelatin film supplemented with carboxymethyl cellulose from pineapple core. Asia-Pacific Journal of Science and Technology, 30(03), APST–30. https://doi.org/10.14456/apst.2025.48

References

Hemung B, Sompholkrang M, Wongchai A, Chanshotikul N, Ueasin N. A study of the potential of by-products from pineapple processing in Thailand: Review article. Int J Health Sci. 2022;6(S4): 12605–12615.

Poonkaew J. Utilization of pineapple waste as goat feed. Seminar of animal science branch, Faculty of Agriculture. Rajamangala University of Technology Srivijaya Nakhon Si Thammarat Campus, Thailand: 2017.

Prakongpan T, Nittihamyong A, Luangpituksa P. Extraction and application of dietary fiber and cellulose from pineapple cores. J Food Sci. 2002;67(4): 1308-1313.

Thomas GM, Paquita EM, Thomas JP. Cellulose ethers. Encyclopedia of polymer science and technology, New York: Wiley (online posting): 2002.

Rachtanapun P, Suriyatem R. Prediction models for moisture sorption syrup of soy protein isolate/carboxymethyl chitosan blend films. J Agric Sci Technol. 2012; A2: 50-57.

Pushpamalar V, Langford SJ, Ahmad M, Lim YY. Optimization of reaction conditions for preparing carboxymethylcellulose from sago waste. Carbohydr Polym. 2006;64: 312-318.

Pormsila W, Kongsantear D, Prasongsuk P. Production and characterization of carboxymethyl cellulose from orange rind. RMUTP Res J. 2019;13(1): 127-138.

Rasid NSAB, Zainol MM, Amin NAS. Synthesis and characterization of carboxymethyl cellulose derived from empty fruit bunch. Sains Malays. 2021;50(9): 2523-2535.

Rachtanapun P, Luangkamin S, Tanprasert K, Suriyatem R. Carboxymethyl cellulose film from durian rind. LWT-Food Science and Technology. 2012;48(1): 52-58.

Saengchu N, Puttnual C, Pongsakchat V, Limroongreungrat K, Sangnark A. Optimum method and conditions of carboxymethyl cellulose production from rice straw. KMUTT Res Dev J. 2008;31(4): 797-809.

Krisdayanti G, Ayn TW, Gita RN. Synthesis and characterization of sodium carboxymethylcellulose from pod husk of Cacao (Theobroma cacao L.). Adv Food Sci Technol. 2017; 5(9): 001-006.

Kanokpanont S, Inthaphunt S, Bunsiri A. Synthesis of Carboxymethyl Cellulose from Young Coconut Husk. Songklanakarin J Plant Sci. 2017; October-December: 60-65.

Arvanitoyannis IS. Totally and partially biodegradable polymer blends based on natural and synthetic macromolecules: preparation, physical properties, and potential as food. packaging materials. J Macromol Sci C. 1991;39(2): 205-271.

Tongnuanchan P, Benjakul S, Prodpran T, Nilsuwan K. Emulsion film on fish skin gelatin and palm oil: physical, structural and thermal properties. Food Hydrocolloid. 2015; 48:248–259.

Banker GS, Gore AY, Swarbrick J. Water vapor transmission properties of free polymer films. J Pharm Pharmacol. 1966;18: 457-466.

Suebsuntorn J, Jirukkakul N. Synthesis and characterization of carboxymethyl cellulose from pineapple core. Food Agric Sci Technol. 2023;9(2): 1-10.

AOAC. Official Methods of Analysis of AOAC International. 17th ed. AOAC International. Maryland, USA: 2000.

Oh JH, Baowu W, Perris DF. Characteristics of edible films made from dairy proteins and zein hydrolysate cross-linked with transglutaminase. Int J Food Sci Technol. 2004;39: 287-294.

ASTM. Standard methods for water vapor transmission of materials (E 96-80). Annual book of ASTM Standards, American Society for Testing and Materials, Philadelphia, PA: 1987.

ASTM. Standard test method for tensile properties of thin plastic sheeting (D882). Annual book of ASTM standards. American Society for Testing and Materials, Philadelphia, PA: 1997.

Jirukkakul N. Physical and antioxidant properties of gelatin film mixed with sesame oil, rice bran oil and coconut oil. Int Food Res J. 2022;29(5): 1020-1031.

Uthaiku A, The study of chemical composition and preparation of film cellulose from Cattail (Typha angustifolia L.) in Saline Soil. Thesis of Master Degree of Science (Chemistry Education). RMU, Thailand: 2018.

Song CL, Othman JB. Synthesis and characterization of lignin-incorporated carboxymethyl cellulose (CMC) films from oil palm lignocellulosic waste. Processes. 2022; 10:2205.

Sukkasem T, Buranachokpaisan K, Anukulwattana K. Mechanical and physical properties of edible film from corn husk waste (Zea mays Linn.). Khon Kaen AGR. J. 2017;25(SUPPL.1): 1222-1228.

Laxmeshwar SS, Madhu KDJ, Viveka S, Nagaraja GK. Preparation and properties of biodegradable film composites using modified cellulose fiber reinforced with PVA. ISRN Polymer Science. 2012;12: 1-8.

Wu W, Zhu W, Zhang Y, Li X. Effect of cellulose nanocrystals on the mechanical properties of starch films. Carbohydr Polym. 2022;288: 119533.

Suwannarat P, Sutthiparinyanont S, Chitropas P. Effect of co-film former and plasticizer on physical and mechanical properties of Tamarind kernel films. Carbohydr Polym. 2014; 1522-1532.

Jinaphan P, Sangsuwan J, Sutthira S, Kamthai S. Properties of carboxy methyl cellulose (CMC) Film from rice straw pulp. Agric Sci J. 2012;43(3): 616-620.

Laohakunjit N, Noomhorm A. Effect of plasticizers on mechanical and barrier properties of rice starch film. Starch/Stärke. 2004;56: 348356.

Kanchanatecha P, Pathumthanasup C, Tattawasart A. Effect of plasticizer on mechanical and water-resistant properties of alcoholic – alkaline treated Mung Bean starch films, 12th GRC KKU. 2011; 1086-1095.

Hernández MP, López RA, Lagarón JM, Gavara R. Formaldehyde crosslinking of gliadin films: effects on mechanical and water barrier properties. Biomacromolecules. 2004;5(2): 415-21.

Mehraliyev F, Kirilenko AP, Choi Y. From measurement scale to sentiment scale: Examining the effect of sensory experiences on online review rating behavior. Tourism Manag. 2020;79: 104096.

Ugartondo V, Mitjans M, Vinardell MP. Comparative antioxidant and cytotoxic effects of lignins from different sources. Bioresour Technol. 2008;99: 6683- 6687.

Published:

License

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.