Sawanya Punyanunt

Department of Food Processing Technology, Faculty of Science and Technology, Muban Chombueng Rajabhat University, Ratchaburi, Thailand

Boontiwa Ninchan

Sugar and Derivatives Analytical Laboratory, Department of Biotechnology, Faculty of Agro-Industry, Kasetsart University, Bangkok, Thailand

Damrongchai Sithisam-ang

Research and Development Group for Bio-Industries (RDB), Thailand Institute of Scientific and Technological Research, Pathum Thani, Thailand

Wannarat Chalermsanyakon

Department of Food Processing Technology, Faculty of Science and Technology, Muban Chombueng Rajabhat University, Ratchaburi, Thailand

Krongsakda Phakthanakanok

Department of Food Processing Technology, Faculty of Science and Technology, Muban Chombueng Rajabhat University, Ratchaburi, Thailand

DOI: https://doi.org/10.14456/apst.2025.6

Keywords: Crispy vegetable Pickled radish Preserved radish Vacuum frying Water pretreatment

Abstract

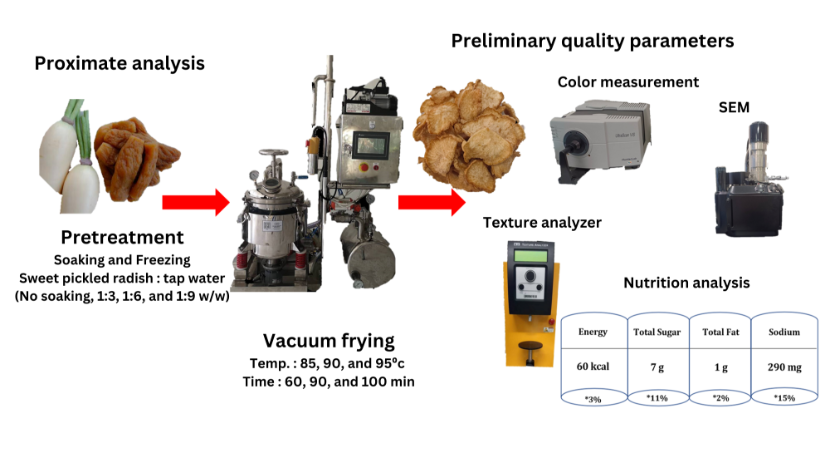

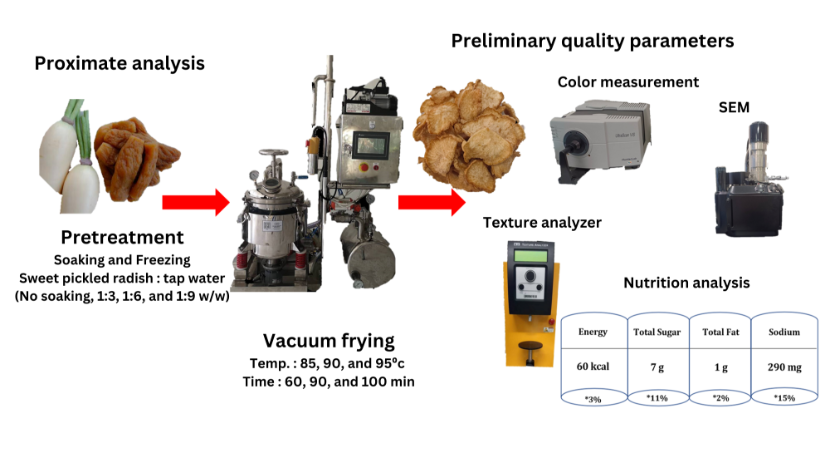

Sweet pickled radish (Huah Chai Bpoh in Thai), which is a famous fermented food in Thailand, is made from white radish (Raphanus sativus L.). To add to its value, sweet pickled radish is processed by vacuum frying to produce a ready-to-eat snack. Water pretreatment was introduced to improve the quality of the sweet pickled radish product. The mass ratios for the pretreatment of sweet pickled radish to tap water were 1:3, 1:6, and 1:9. Then, it was fried at temperatures of 85, 90, and 95°C for 60, 90, and 100 min under vacuum conditions. The product quality parameters such as average diameter, visual appearance, color, and textural characteristics were examined. The results found that water pretreatment also decreased the total soluble solid content (TSS, °Brix) in the pickled radish sample, and the lowest TSS was observed at a ratio of 1:9. Such a pretreatment ratio induced the highest average diameter of fried product because the losing cellular structure strength after pretreatment promoted larger volume expansion during vacuum frying. Vacuum frying conditions comprising a temperature of 85°C for 100 min exhibited less browning and produced the highest hard texture. Moreover, Scanning electron microscopy (SEM) images of the fried product were different from fresh sweet pickled radish, as observed by larger pore sizes contained inside the fried product structures.

How to Cite

Punyanunt, S. ., Ninchan, B. ., Sithisam-ang, D. ., Chalermsanyakon, W. ., & Phakthanakanok, K. . (2025). Development of crispy-sweet pickled radish products by vacuum frying and water pretreatment. Asia-Pacific Journal of Science and Technology, 30(01), APST–30. https://doi.org/10.14456/apst.2025.6

References

Indrati N, Phonsatta N, Poungsombat P, Khoomrung S, Sumpavapol P, Punya A. Metabolic profiles alteration of Southern Thailand traditional sweet pickled mango during the production process. Front Nutr. 2022;9:934842.

Li X, Liu D. Effects of wheat bran co-fermentation on the quality and bacterial community succession during radish fermentation. Food Res Int. 2022;157:111229.

Wu S-M, Wu C-P, Lin Y-H, Wu Y-H, Huang B-C, Wang C-Y. Effect of high pressure pretreatment on myrosinase-glucosinolate system, physicochemical and bacterial properties during fermentation of brine-pickled radishes. Food Res Int. 2022;162(Pt A):112018.

Manzoor S, Masoodi FA, Rashid R, Ganaie TA. Quality changes of edible oils during vacuum and atmospheric frying of potato chips. Innov Food Sci Emerg Technol. 2022;82:103185.

Belkova B, Hradecky J, Hurkova K, Forstova V, Vaclavik L, Hajslova J. Impact of vacuum frying on quality of potato crisps and frying oil. Food Chem. 2018;241:51-59.

Yamsaengsung R, Ariyapuchai T, Prasertsit K. Effects of vacuum frying on structural changes of bananas. J Food Eng. 2011;106(4):298-305.

Patra A, Prasath VA, Sutar PP, Pandian NKS, Pandiselvam R. Evaluation of effect of vacuum frying on textural properties of food products. Food Res Int. 2022;162(Pt B):112074.

Ledbetter M, Blidi S, Ackon S, Bruno F, Sturrock K, Pellegrini N, et al. Effect of novel sequential soaking treatments on Maillard reaction products in potato and alternative vegetable crisps. Heliyon. 2021;7(7):e07441.

Andrés-Bello A, García-Segovia P, Martínez-Monzó J. Vacuum Frying: An alternative to obtain high-quality dried products. Food Eng Rev. 2011;3(2):63-78.

Tabtiang S, Prachayawarakorn S, Soponronnarit S. Optimum condition of producing crisp osmotic banana using superheated steam puffing. J Sci Food Agric. 2017;97(4):1244–1251.

Shyu S-L, Hwang LS. Effects of processing conditions on the quality of vacuum fried apple chips. Food Res Int. 2001;34(2–3):133-142.

AOAC International. Official methods of analysis of AOAC international. 20th ed. Maryland: Asssociation of Official Analytical Chemists; 2016.

AOAC International. Official methods of analysis of AOAC international. 21st ed. Washington: Asssociation of Official Analytical Chemists; 2019.

Saencom S, Chiewchan N, Devahastin S. Production of dried ivy gourd sheet as a health snack. Food Bioprod Process. 2011;89(4):414-421.

Akinpelu OR, Idowu MA, Sobukola OP, Henshaw FO, Sanni SA, Bodunde G, et al. Optimization of processing conditions for vacuum frying of high quality fried plantain chips using response surface methodology (RSM). Food Sci Biotechnol. 2014;23(4):1121-1128.

Murtey MD, Ramasamy P. Life science sample preparations for scanning electron microscopy. Acta Microsc. 2021;30(2):80-91.

Thuy NM, My LTD, Ben TC, Tai NV. Development and quality evaluation of healthy soup for children making from banana and other vegetables. Asia Pac J Sci Technol. 2023;28(01):APST-28-01-9.

Feng S, Bi J, Yi J, Li X, Li J, Ma Y. Cell wall polysaccharides and mono-/disaccharides as chemical determinants for the texture and hygroscopicity of freeze-dried fruit and vegetable cubes. Food Chem. 2022;395:133574.

Hu Y, Liu X, Wu X, Zhang Z, Wu D, Chen C, et al. Several natural phytochemicals from Chinese traditional fermented food-pickled Raphanus sativus L.: Purification and characterization. Food Chem X. 2022;15:100390.

Tabtiang S, Yodrux A, Nimmol C, Prachayawarakorn S, Soponronnarit S. Effects of thermal pretreatment and puffing medium variously modify the microstructure and quality of crisps obtained from two banana varieties. J Stored Prod Res. 2023;104:102199.

Tabtiang S, Yodrux A, Nimmol C, Prachayawarakorn S, Soponronnarit S. Effects of variety and ripening level on chemical composition, microstructure change, and qualities of crisp bananas. J Food Process Preserv. 2022;46(3):1-15.

Thongcharoenpipat C, Yamsaengsung R. Microwave-assisted vacuum frying of durian chips: Impact of ripening level on the drying rate, physio-chemical characteristics, and acceptability. Food Bioprod Process. 2023;138:40-52.

Diamante L, Presswood HA, Savage G, Vanhanen L. Vacuum fried gold kiwifruit: Effects of frying process and pre-treatment on the physico-chemical and nutritional qualities. Int Food Res J. 2011;638:632-638.

Mesias M, Delgado-Andrade C, Morales FJ. Risk/benefit evaluation of traditional and novel formulations for snacking: Acrylamide and furfurals as process contaminants. J Food Compost Anal. 2019;79:114-121.

Published:

License

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.