Swastika Dewi

Food Technology Study Program, Department of Agriculture, Faculty of Animal and Agricultural Sciences, Universitas Diponegoro, Jl. Prof Soedarto, S.H., Tembalang, Semarang 50275, Indonesia

Rafli Zulfa Kamil

Food Technology Study Program, Department of Agriculture, Faculty of Animal and Agricultural Sciences, Universitas Diponegoro, Jl. Prof Soedarto, S.H., Tembalang, Semarang 50275, Indonesia

Hasna Yumnaningsih

Food Technology Study Program, Department of Agriculture, Faculty of Animal and Agricultural Sciences, Universitas Diponegoro, Jl. Prof Soedarto, S.H., Tembalang, Semarang 50275, Indonesia

Setya Budi Muhammad Abduh

Food Technology Study Program, Department of Agriculture, Faculty of Animal and Agricultural Sciences, Universitas Diponegoro, Jl. Prof Soedarto, S.H., Tembalang, Semarang 50275, Indonesia

DOI: https://doi.org/10.14456/apst.2025.69

Keywords: Probiotics Orange Microencapsulation Microbeads Calcium lactate

Abstract

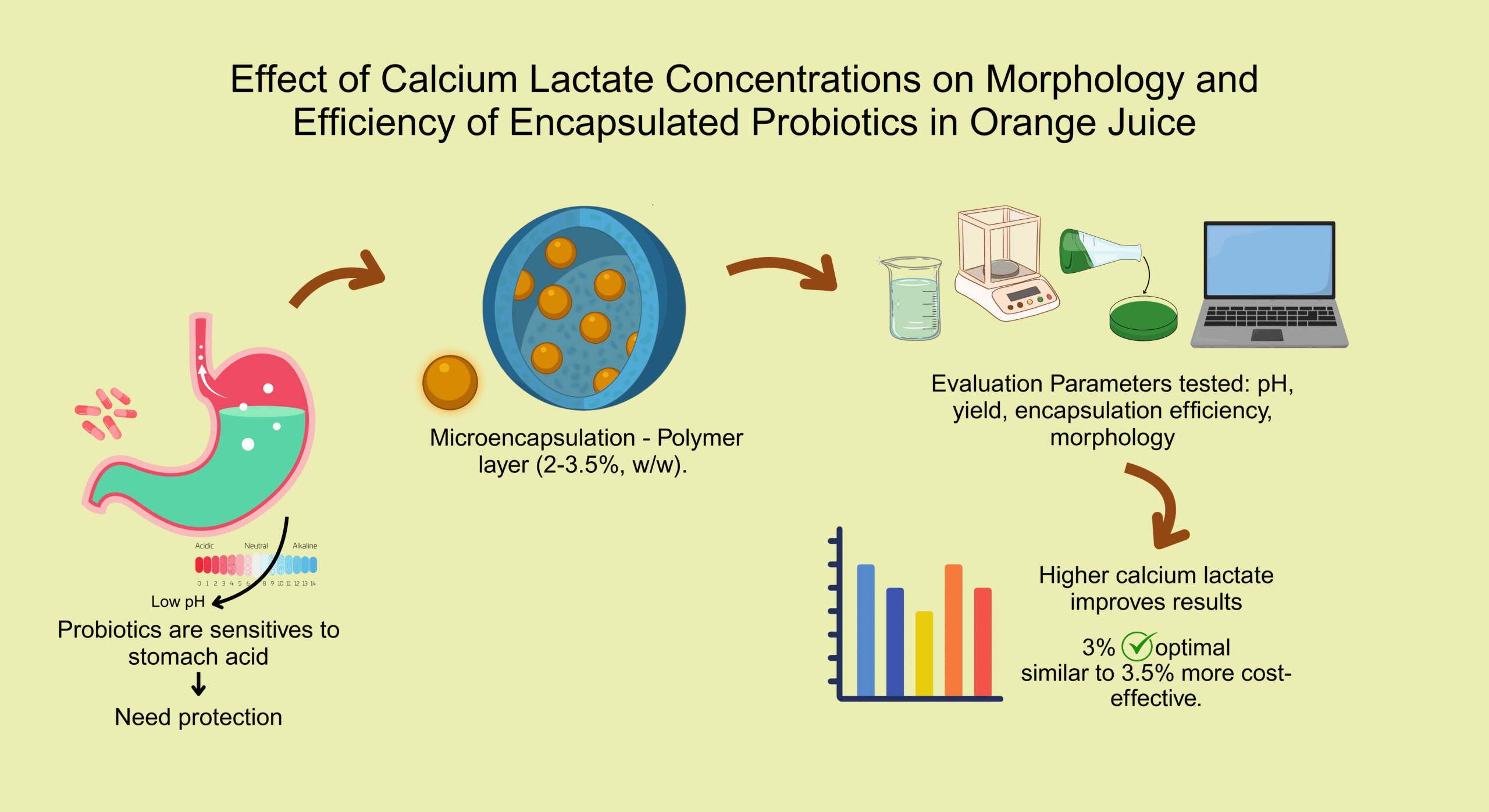

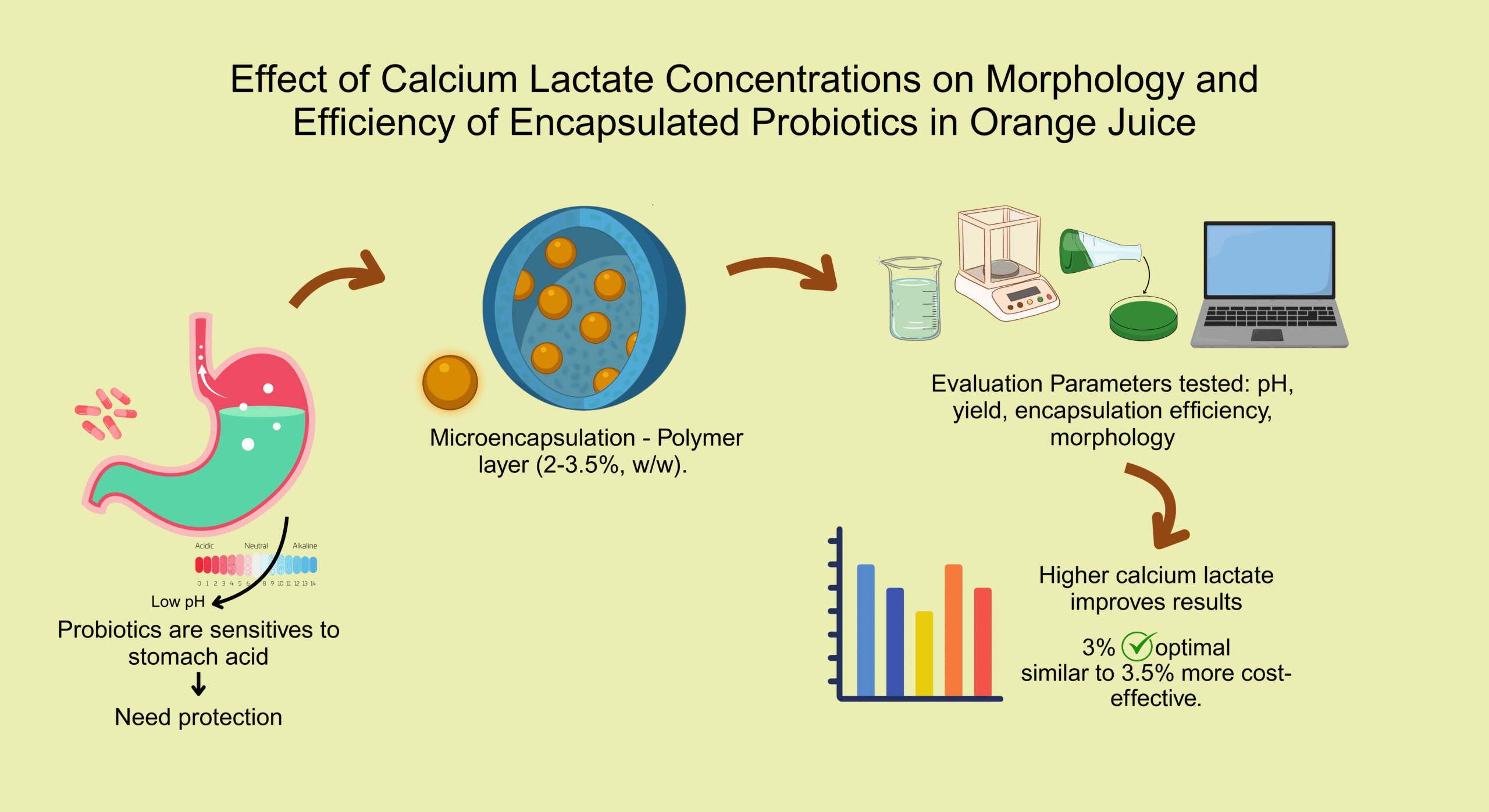

Probiotics are good bacteria required by the body but unable to survive in stomach acidic conditions, leading to the need for a coating agent. The technology that can maintain the viability of probiotics is microencapsulation, which includes coating core substances with polymer wall layers into micro-sized particles. Therefore, this research aimed to determine the optimal level of calcium lactate in preparing probiotic orange juice microbeads against pH, yield, encapsulation efficiency, and morphology. Microencapsulation was used with extrusion methods, while probiotic orange juice microbeads were manufactured using 2%, 2.5%, 3%, and 3.5% calcium lactate (% w/w). The parameters tested were pH value, total yield, encapsulation efficiency, and morphology. The results showed that the addition of a higher calcium lactate level led to a significant increase in morphology, encapsulation efficiency, yield value, and pH value but not in the solidity attribute. Calcium lactate of 3% initiated an insignificant difference in morphology, encapsulation efficiency, yield, and pH value compared to a 3.5% level. Based on production costs, 3% calcium lactate was considered more optimal than the 3.5% level for the manufacture of probiotic orange juice microbeads.

How to Cite

Dewi, S., Zulfa Kamil, R., Yumnaningsih, H. ., & Budi Muhammad Abduh, S. . (2025). Effect of calcium lactate concentrations on morphology and efficiency of encapsulated probiotics in orange juice. Asia-Pacific Journal of Science and Technology, 30(05), APST–30. https://doi.org/10.14456/apst.2025.69

References

Abbas A. The potential of functional foods and their role in improving the health of increasingly vulnerable humans. Teknosains Media Inf Sains Dan Teknol. 2020;14(2):176–186.

Wulandari R, Indriana D, Amalia AN. Hydrocolloid application as an emulsifier in chocolate processing. J Ind Has Perkeb. 2019;14(1):2-8.

Nurhamidah A, Warsidah W, Idiawati N. Isolation and characterization of lactic acid bacteria (LAB) from ale-ale and cincalok. J Laut Khatulistiwa. 2020;2(3):8-15.

Purwandhani SN. Folate Biosynthesis by lactic acid bacteria. Agrotech. 2016;1(1):11–18.

R. Haryo Bimo Setiarto, 2 HDK, Betty Sri Laksmi Jenie TK. Development of microencapsulation technology for probiotic bacteria and its health benefits. J Vet. 2019;19(4):574–589.

Rajagukguk WJ, Dwi W, Sayekti SS. Consumers’ attitudes and purchasing decisions on local and imported oranges in bandar lampung. JIIA.2013;1(4):351–357.

Wati RR, Sriwidodo S, Chaerunisa AY. Enhancement of phytoconstituent stability through a microencapsulation approach. Maj Farmasetika. 2022;7(1):3-9.

Abbas P, Mayangsari CP, Gunawan R. The effect of Lactobacillus acidophilus, Streptococcus thermophilus, and Bifidobacterium longum probiotics on bilirubin levels of neonates with hyperbilirubinemia. Sains Med J Kedokt Kesehat. 2023;14(2):5-8.

R. Haryo Bimo Setiarto NW, Octavia ND, Himawan HC. Production of fermented papaya juice (Carica papaya) as an antihypercholesterolemia probiotic drink. J Litbang Ind. 2022;2014(2):73–81.

Murdinah, M. The use of alginate in lemon extract effervescent powder production. J Pengolah Has Perikan Indones. 2015;18(2):177–189.

Dwiloka B, Rahman FT, Mulyani S. Nilai pH value, Viscosity and hedonic of sweet orange juice with added milkfish bone gelatin. Agri Health J Agri food Nutr Public Heal. 2022;2(2):10-17.

Hasyim H, Rahim A, Rostiati. Physical, chemical and organoleptic characteristics of jelly candy from soursop fruit juice at varying agar-agar concentrations. J Agrotekbis. 2015;3(4):463–474.

Alahakoon AU, Jayasena DD, Jung S, Kim HJ, Kim SH, Jo C. Antimicrobial effect of calcium chloride alone and combined with lactic acid injected into chicken breast meat. Korean J Food Sci Anim Resour. 2014;34(2):221–229.

Cahyono K, Sumardi S, Irawan B, Wahyuningsih S, Nurcahyani E. Immobilization of lactic acid bacteria using zeolite and sodium alginate. J Ilm Farm Farmasyifa. 2021;4(1):33–40.

Ratnasari N, Kusumawati N, Kuswardhani I. The Effect of sodium alginate concentration as a trap for Lactobacillus acidophilus Fncc 0051 cells and storage time on the number of released cells and carrier characteristics. J Teknol Pangan dan Gizi Food Technol Nutr. 2017;13(2):81–86.

Hasan A, Taufik M, Bande LOS, Khaeruni A, Mallarangeng R, Gusnawaty HS, et al. Morphometric analysis of chili leaves with yellow curly symptom using digital image processing approach and data mining algorithm. J Fitopatol Indones. 2023;19(6):231–237.

Prastiti R, Mulyani S, Masykuri. Microbiological characteristics and texture of probiotic ice cream with fresh milk raw material combined with purple sweet potato (Ipomoea batatas). Anim Agric J. 2013;18(2(4)):127–136.

Mansur DS, Hidayat MN. Resistance of lactic acid bacteria from broiler digestive tract to pH and bile salts. J Ilmu dan Ind Peternak Anim Husb Sci Ind. 2019;5(1):2-7.

Diza YH, Asben A, Anggraini T. Isolation, identification and preparation of dry preparations of Lactic Acid Bacteria that have the potential as probiotics from dadih from Sijunjung, West Sumatra. J Litbang Ind. 2020;10(2):155-158.

Arifa AN, Suharti PH. The effect of solvent amount on yield in making moringa hand sanitizer (Moringe Oleifera). DISTILAT J Teknol Separasi. 2023;7(2):341–346.

Wardani EK, Zulaekah S, Purwani E. The effect of adding pineapple juice (Ananas comosus) on the number of lactic acid bacteria (LAB) and the pH value of soyghurt. J Kesehat. 2017;10(1):6-8.

Sumanti DM. The effect of lactobacillus acidophilus bacteria concentration on the characteristics of synbiotic porridge made from composite flour. J. Universitas Padjajaran. 2017;2:2-5.

Zdilla MJ, Hatfield SA, McLean KA, Cyrus LM, Laslo JM, Lambert HW. Circularity, solidity, axes of a best fit ellipse, aspect ratio, and roundness of the foramen ovale: A morphometric analysis with neurosurgical considerations. J Craniofac Surg. 2016;27(1):222–228.

Saria TR, Surjoseputroa S, Setijawatia E. The effect of calcium lactate concentration on the physicochemical properties of rice paper made from ir 64 rice. Teknol Pangan dan Giz. 2020;19(1):22–28.

Maharani AA, Husni A, Ekantari N. The effect of extraction methods on characteristic of sodiumAlginate from brown seaweed sargassum fluitans. Masy Pengolah Has Perikan Indones. 2017;20(3):478–487.

Caoa L, Lua W, Mataa A, Nishinarib K, Fanga Y. Polimer Karbohidrat Gelasi alginat dan pektin berbasis model kotak telur. Sebuah Tinjauan. 2020;24:2-5.

Cao L, Lu W, Mata A, Nishinari K, Fang Y. Egg-box model-based gelation of alginate and pectin: A review. Carbohydr Polym. 2020;242:116389.

Raharjo S, Utama Z. The Effect of particle size and proportion of guluronate-manurnate in alginate on the physical and sensory properties of restructured products from soursop fruit. J Teknol dan Industri Pangan. 2003;14:206-213.

Cao L, Lu W, Mata A, Nishinari K, Fang Y. Egg-box model-based gelation of alginate and pectin: A review. Carbohydr Polym. 2020;2:42-43.

Sari TR, Surjoseputro S, Setijawaty E. The effect of calcium lactate concentration on the physicochemical properties of rice paper made from ir 64 rice. J Teknol Pangan dan Gizi Food Technol Nutr. 2020;19(1):23–28.

Mardikasari SA, Suryani, Akib NI, Indahyani R. Microencapsulation of mefenamic acid using chitosan polymer and sodium alginate by ionic gelation method. J Farm Galen Pharmacy. 2020;6(2):192–203.

Wibowo AA, Suryandari AS, Naryono E, Pratiwi VM, Suharto M, Adiba N. Encapsulation of clove oil within Ca-alginate-gelatine complex: Effect of process variables on encapsulation efficiency. J Tek Kim dan Lingkung. 2021;5(1):71–77.

Kurniawan R, Rahmat D. Controlled-release microencapsulation of lansoprazole using a combination of hydroxypropyl methylcellulose phthalate and sodium alginate via ionotropic gelation. J Ilmu Kefarmasian Indones. 2015;14(1):86–92.

Milla L El, Indrani DJ, Irawan B. Hydroxyapatite alginate scaffold porosity testing and analysis. ODONTO Dent J. 2018;5(1):4-9.

Published:

License

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.