Adisorn Buranawong

Material Innovation Research Laboratory, Department of Physics, Faculty of Sciences, Burapha University

Nirun Witit-anun

Material Innovation Research Laboratory, Department of Physics, Faculty of Sciences, Burapha University

DOI: https://doi.org/10.14456/apst.2025.43

Keywords: Chromium content Hardness Hard coating Thin film TiCrN Reactive magnetron sputtering

Abstract

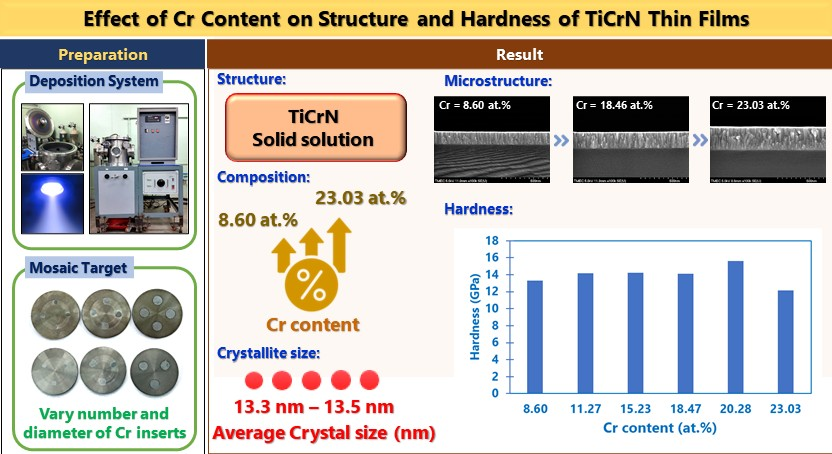

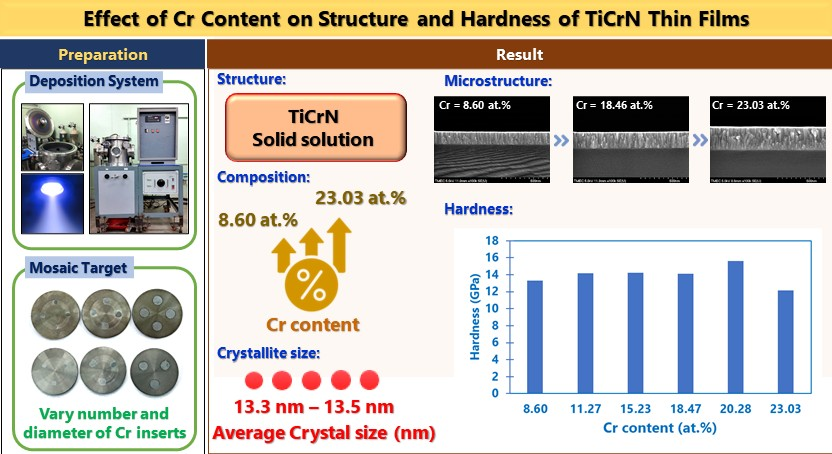

The aim of this study was to investigate the effects of chromium (Cr) content on the structure and hardness of titanium chromium nitride (TiCrN) thin films deposited on Si substrates using reactive direct current magnetron sputtering from mosaic Ti-Cr targets. The crystal structure, chemical composition, surface morphology, microstructure, and hardness of the thin films were characterized by X-ray diffraction (XRD), energy-dispersive X-ray spectroscopy (EDS), field emission scanning electron microscopy (FE-SEM), and nano-indentation. The results showed that the as-deposited films were formed as (Ti, Cr)N solid solutions with face-centered cubic structures in the (111), (200), and (220) planes, as determined from the XRD patterns. The lattice parameters were in the range of 4.206–4.282 Å with a nanocrystalline structure, and the average crystal size was 13.3–15.7 nm. According to the EDS analysis results, the Ti, Cr, and N contents were observed at different ratios. According to the microscopic FE-SEM image, the Cr content influences the surface morphology and cross-section of the deposited film. According to the nano-indentation results, the hardness of the deposited films increased and then decreased (12.17–15.64 GPa) with increasing Cr content. The highest hardness was obtained at a Cr content of 20.28 at.% with an average crystallite size of 13.4 nm.

How to Cite

Buranawong, A., & Witit-anun, N. (2025). Effect of Cr Content on Structure and Hardness of TiCrN Thin Films. Asia-Pacific Journal of Science and Technology, 30(03), APST–30. https://doi.org/10.14456/apst.2025.43

References

Jijun Y, Mingjin JL, Yuanyou Y, Ning L. Effect of N2 gas injection parameters on structure and properties of TiN thin films prepared by reactive gas pulse sputtering. Surf Coat Tech. 2017;311:391-397.

Richter NA, Yang B, Barnard JP, Niu T, Sheng X, Shaw D, Watanabe M, et al. Significant texture and wear resistance improvement of TiN coatings using pulsed DC magnetron sputtering. Appl Surf Sci. 2023;635:157709.

Jie X, Miao G, Linlin L, Jiyun W. Research on the resistivity and infrared emissivity of nonstoichiometric TiCrN films. J Mater Eng Perform. 2023;32:3772-3779.

Chen S, Luo D, Zhao, G. Investigation of the properties of TixCr1-xN coatings prepared by cathodic arc deposition. Phys Procedia. 2013;50:163-168.

Wolfe DE, Gabriel BM, Reedy, MW. Nanolayer (Ti, Cr) N coatings for hard particle erosion resistance. Surf Coat Tech. 2011;205:4569-4576.

Mitin VS, Sharipov EI, Mitin AV. High deposition rate magnetrons: key elements and advantages. Surf Eng. 2006;22:5-10.

Compaan AD, Gupta A, Lee S, Wang S, Drayton J. High efficiency, magnetron sputtered CdS/CdTe solar cells. Sol Energy. 2004;77:815-822.

Golosov DA, Melnikov SN, Dostanko AP. Calculation of the elemental composition of thin films deposited by magnetron sputtering of mosaic targets. Surf Eng Appl Electrochem. 2012;48:52-59.

Aperador W, Delgado A, Caicedo JC. Analysis of corrosion degradation of TiCrN coatings subjected to high temperatures. Int J Electrochem Sci. 2017; 4502-4514.

Mehr Ali-Ko, Mehr Ab-Ko. Reactive grid-assisted co-sputtering of titanium and chromium in a pure nitrogen atmosphere: uniformity, optics, and structure of the Ti–Cr–N films. Ceram Int. 2022;48:4921-4929.

Paksunchai C, Denchitcharoen S, Chaiyakun S, Limsuwan P. Growth and characterization of nanostructured TiCrN films prepared by DC magnetron co sputtering. J Nanomater 2014;2014:1-9.

Paksunchai C, Denchitcharoen S, Chaiyakun S, Limsuwan P. Effect of sputtering current on structure and morphology of (Ti1-xCrx)N thin films deposited by reactive unbalanced magnetron co-sputtering. Procedia Eng. 2012;32:875-881.

Cullity BD. Elements of X-RAY diffraction. 2th ed. Canada: Addison-Wesley; 1978.

Xu KW, Hou GL, Hendrix BC, He JW, Sun Y, Zheng S, Bloyce A, Bell T. Prediction of nanoindentation hardness profile from a load-displacement curve. J Mater Res. 1998;13:3519-26.

Ogneva TS, Ruktuev AA, Cherkasova NY, Malyutina YN, Khomyakov MN, Burov VG, Bataev IA. NiAl coatings produced by magnetron sputtering from mosaic targets. J Mater Eng Perform. 2024;33:1718-1731.

Thampi VVA, Bendavid A, Subramanian B. Nanostructured TiCrN thin films by pulsed magnetron sputtering for cutting tool applications. Ceram Int. 2016;42:9940-9948.

Mehr Kl, Meymian MRZ, Mehr KA. Nanoindentation and nanoscratch studies of submicron nanostructured Ti/TiCrN bilayer films deposited by RF-DC co-sputtering method. Ceram Int. 2018;44:21825-21834.

Buranawong A, Witit-anun N, Chaiyakun S, Pokaipisit A, Limsuwan P. The effect of titanium current on structure and hardness of aluminium titanium nitride deposited by reactive unbalanced magnetron

co-sputtering. Thin Solid Film. 2011;519:4963-4968.

Ghorannevis Z, Akbarnejad E, Ghoranneviss M. Effects of various deposition times and RF powers on CdTe thin film growth using magnetron sputtering. J Theor Appl Phys 2016;10:225-231.

Zhang ZG, Rapaud O, Bonasso N, Mercs D, Dong, C. Coddet C. Microstructures and corrosion behaviors of Zr modified CrN coatings deposited by DC magnetron sputtering. Vacuum. 2008;82:1332-1336.

Callister, WD. Materials science and engineering: an introduction. 7th ed. New York: John Wiley & Sons; 2007.

Shah HN, Jayaganthan, R. Influence of Al Contents on the microstructure, mechanical, and wear properties of magnetron sputtered CrAlN coatings. J Mater Eng Perform. 2012;21:2002-2019.

Lee DB, Kim MH, Lee YC, Kwon SC. High temperature oxidation of TiCrN coatings deposited on a steel substrate by ion plating. Surf Coat Tech. 2001;141:232-239.

Lee LW, Tien SK, Kuo YC, Chen CM. The mechanical properties evaluation of the CrN coatings deposited by the pulsed DC reactive magnetron sputtering. Surf Coat Tech. 2006;200:3330-3335.

Shah HN, Chawla V, Jayaganthan R, Kaur D. Microstructural characterizations and hardness evaluation of d.c. reactive magnetron sputtered CrN thin films on stainless steel substrate. Bull Mater Sci. 2010;33:103-110.

Vishnyakov VM, Bachurin VI, Minnebaev KF, Valizadeh R, Teer DG, Colligon JS, et al. Ion assisted deposition of titanium chromium nitride. Thin Solid Films. 2006;497:189-195.

Liu L, Zhang J, Ai C. Nickel-based superalloys. London: Elsevier Science. 2020;1-11.

Callister Jr. WD, Rethwisch DG. Materials science and engineering: an introduction. 8th ed. New Jersey: John Wiley & Sons; 2010.

Lee KH, Park CH, Yoon YS, Lee JJ. Structure and properties of Ti Cr N coatings produced. Thin Solid Films. 2001;385:167-173.

Hones P, Sanjinés R, Lévy F. Sputter deposited chromium nitride based ternary compounds for hard coatings. Thin Solid Films. 1998;332:240-246.

Whang SH. Nanostructured metals and alloys. 1st ed. Cambridge: Woodhead Publishing; 2011.

Published:

License

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.