Juntima Chungsiriporn

Division of Chemical Engineering, Faculty of Engineering, Prince of Songkla University, Songkhla, Hat Yai, Songkhla 90112, Thailand

Prukraya Pongyeela

Division of Chemical Engineering, Faculty of Engineering, Prince of Songkla University, Songkhla, Hat Yai, Songkhla 90112, Thailand

Nirana Chairerk

Division of Chemical Engineering, Faculty of Engineering, Prince of Songkla University, Songkhla, Hat Yai, Songkhla 90112, Thailand

Kanjana Kantakapun

Division of Chemical Engineering, Faculty of Engineering, Prince of Songkla University, Songkhla, Hat Yai, Songkhla 90112, Thailand

Jutarut Iewkittayakorn

Division of Molecular Biotechnology and Bioinformatics, Faculty of Science, Prince of Songkla University, Hat Yai, Songkhla 90112, Thailand

DOI: https://doi.org/10.14456/apst.2025.44

Keywords: Cocoa juice Cocoa pulp Fermented cocoa beans Fermenter Heating chamber

Abstract

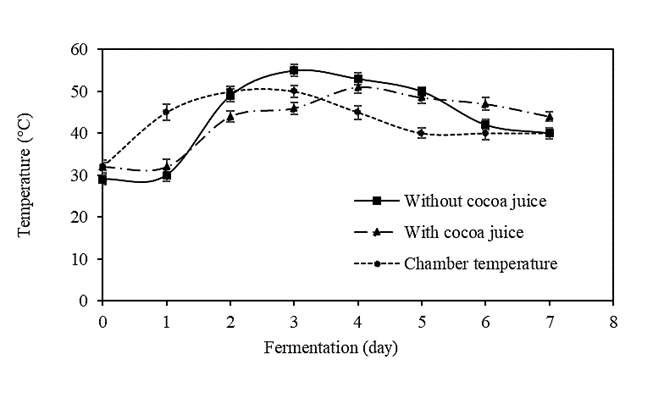

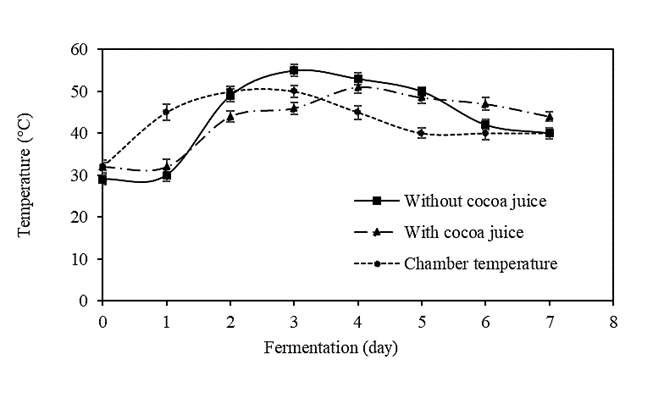

The fermentation of cocoa beans is a key process that shapes chocolate flavor. This study aimed to assess how various fermentation parameters influence cocoa bean quality. The main parameters of interest were the temperature of cocoa beans during fermentation, which was controlled with a heating chamber, and the presence in the fermentation substrate of cocoa juice, which can be separated from the cocoa pulp before fermentation. Aeration frequency (every day or every 2 days) and the turning start times (day 1 or day 2) were varied. Washing the fermented beans before drying was also monitored for the effecting to quality of dried cocoa beans. The temperature, pH value, bacterial count and composition of the cocoa beans were measured, and a standard cut test was performed. Results indicated that cocoa bean temperature in the fermenter was consistently 5°C higher than the heating chamber setting. The cut test confirmed that separating the cocoa juice from the pulp before fermentation gives the best bean quality, with a success rate of 86–89%. In addition, the fermented beans had higher total phenolic and total flavonoid contents, and higher antioxidant activity compared to beans that were fermented with the cocoa juice. Separating the cocoa juice from the pulp, turning the beans every day starting from day 1, and washing the beans before drying resulted in higher fermentation temperatures and lower fermentation substrate acidity, thereby reducing the acidity of the beans. These improvements in the fermentation process ensure the production of high-quality fermented cocoa beans.

How to Cite

Chungsiriporn, J., Pongyeela, P. ., Chairerk , N. ., Kantakapun , K. ., & Iewkittayakorn , J. . (2025). Effect of heated fermentation and separation of cocoa juice from cocoa pulp on the quality of fermented cocoa beans. Asia-Pacific Journal of Science and Technology, 30(03), APST–30. https://doi.org/10.14456/apst.2025.44

References

Janick J, Paull RE. The Encyclopedia of fruit and nuts. CABI. 2014;8:321–328.

Crafack M, Mikkelsen MB, Saerens S, Knudsen M, Blennow A, Lowor S, et al. Influencing cocoa flavour using Pichia kluyveri and Kluyveromyces marxianus in a defined mixed starter culture for cocoa fermentation. Int J Food Microbiol. 2013;167(1):103–116.

Aroyeun SO, Adegoke GO, Varga J, Teren J. Grading of Fermented and Dried Cocoa Beans Using Fungal Contamination, Ergosterol Index and Ochratoxin a Production. Mycobiology. 2009;37(3):215–217.

Duarte WF, Dias DR, Oliveira JM, Teixeira JA, Almeida e Silva JB de, Schwan RF. Characterization of different fruit wines made from cacao, cupuassu, gabiroba, jaboticaba and umbu. LWT. 2010;43(10):1564–1572.

Gutiérrez-Ríos HG, Suárez-Quiroz ML, Hernández-Estrada ZJ, Castellanos-Onorio OP, Alonso-Villegas R, Rayas-Duarte P, et al. Yeasts as producers of flavor precursors during cocoa bean fermentation and their relevance as starter cultures: A review. Fermentation. 2022;8(7).

Emmanuel OA, Jennifer Q, Agnes SB, Jemmy ST, Firibu KS. Influence of pulp-preconditioning and fermentation on fermentative quality and appearance of Ghanaian cocoa (Theobroma cacao) beans. Int Food Res J. 2012;19(1):127–133.

Chagas JGCA, Ferreira NR, Lopes AS. The microbiota diversity identified during the cocoa fermentation and the benefits of the starter cultures use: an overview. Int J Food Sci Technol. 2021;56(2):544–552.

Guzmán-Alvarez RE, Márquez-Ramos JG. Fermentation of cocoa beans [Internet]. 2024 [cited 2024 May 1]. Available from: www.intechopen.com.

Caligiani A, Cirlini M, Palla G, Ravaglia R, Arlorio M. GC-MS detection of chiral markers in cocoa beans of different quality and geographic origin. Chirality. 2007;19(4):329–334.

Payne MJ, Hurst WJ, Miller KB, Rank C, Stuart DA. Impact of fermentation, drying, roasting, and dutch processing on epicatechin and catechin content of cacao beans and cocoa ingredients. J Agric Food Chem. 2010;58(19):10518–10527.

Apriyanto M. Changes in chemical properties of dreid cocoa (Theobroma cacao) beans during fermentation. Int J Fermented Foods. 2016;5(1):11.

Guda P, Gadhe S, Jakkula S. Drying of cocoa beans by using different techniques. Int J Agric Innov Res. 2017;5(5):2319-1473.

Jinap S, Thien J. Effect of drying on acidity and volatile fatty acids content of cocoa beans. J Sci Food Agric. 1994;65(1):67-75.

Camu N, De Winter T, Addo SK, Takrama JS, Bernaert H, Vuyst L De. Fermentation of cocoa beans: Influence of microbial activities and polyphenol concentrations on the flavour of chocolate. J Sci Food Agric. 2008;88(13):2288–2297.

Oa O, Ibitoye O, Os O, Oke O, Ogungbemi K. Evaluation of the quality characteristics of cocoa bean dried using different drying techniques. Innov J Agric Sci. 2022;10:5.

Hu Z, Tang X, Liu J, Zhu Z, Shao Y. Effect of parboiling on phytochemical content, antioxidant activity and physicochemical properties of germinated red rice. Food Chem. 2017;214:285–292.

Kedare SB, Singh RP. Genesis and development of DPPH method of antioxidant assay. J Food Sci Technol. 2011;48(4):412–422.

Deus VL, Bispo ES, Franca AS, Gloria MBA. Understanding amino acids and bioactive amines changes during on-farm cocoa fermentation. J Food Compos Anal. 2021;97.

Agyirifo DS, Wamalwa M, Otwe EP, Galyuon I, Runo S, Takrama J, et al. Metagenomics analysis of cocoa bean fermentation microbiome identifying species diversity and putative functional capabilities. Heliyon. 2019;5(7).

Verce M, Schoonejans J, Hernandez Aguirre C, Molina-Bravo R, Vuyst L De, Weckx S. A combined metagenomics and metatranscriptomics approach to unravel costa rican cocoa box fermentation processes reveals yet unreported microbial species and functionalities. Front Microbiol. 2021;12:641185.

Ayob MA. Effects of different fermentation approaches on the microbiological and physicochemical changes during cocoa bean fermentation [Internet]. 2024 [cited 2024 May 1]. Available from: http://www.ifrj.upm.edu.my.

Wahyuni MF, Yunita D, Aisyah Y, Lahmer RA, Mugampoza D. Proceeding of The 8 th AIC: Health and Life Sciences. 2018.

Schwan RF, Wheals AE. The microbiology of cocoa fermentation and its role in chocolate quality. Crit Rev Food Sci Nutr. 2004;44(4):205–221.

Moreira IM da V, Vilela L de F, Santos C, Lima N, Schwan RF. Volatile compounds and protein profiles analyses of fermented cocoa beans and chocolates from different hybrids cultivated in Brazil. Food Res Int. 2018;109:196–203.

Hernani, Hidayat T, Mulyawanti I. The usage of dried starter for re-fermentation of unfermented cocoa beans. In: IOP Conference Series: Earth and Environmental Science. IOP Publ., Oct. 2019.

Amankwah, Adomako DA. Knowing your cocoa and its quality parameters: The pH factor [Internet]. 2024 [cited 2024 May 3]. Available: https://thecocoapost.com/knowing-your-cocoa-and-its-quality-parametres-the-ph-factor/.

Elwers S, Zambrano A, Rohsius C, Lieberei R. Differences between the content of phenolic compounds in Criollo, Forastero and Trinitario cocoa seed (Theobroma cacao L.). Eur Food Res Technol. 2009;229(6):937–948.

Afoakwa EO, Paterson A, Fowler M, Ryan A. Flavor formation and character in cocoa and chocolate: A critical review. Crit Rev Food Sci Nutr. 2008;48(9):840–857.

Aprotosoaie AC, Luca SV, Miron A. Flavor chemistry of cocoa and cocoa products-an overview. Compr Rev Food Sci Food Saf. 2016;15(1):73–91.

Published:

License

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.