Jaturong Langkapin

Faculty of Engineering, Rajamangala University of Technology

Sunan Parnsakhorn

Faculty of Engineering, Rajamangala University of Technology Thanyaburi

Orawan Oupathumpanont

Faculty of Home Economics Technology, Rajamangala University of Technology Thanyaburi

DOI: https://doi.org/10.14456/apst.2025.80

Keywords: Popped rice Khao Sangyod Krayasart bars Drying Physicochemical

Abstract

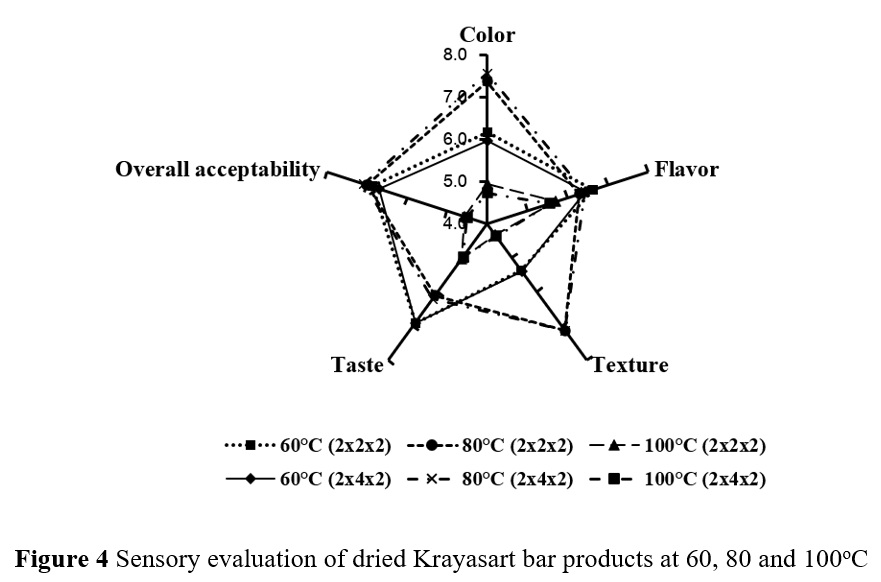

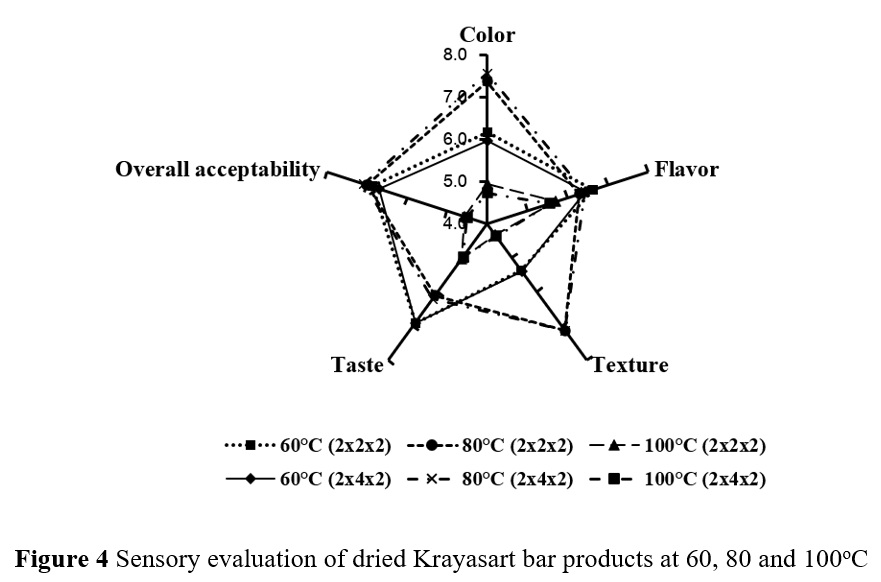

This study aimed to enhance the nutritional profile and sensory acceptability of dried Krayasart bars by incorporating popped Sangyod rice and stevia, and to evaluate their physicochemical and sensory characteristics. Three formulations were developed using 10.5 g, 12.5 g, and 14.5 g of popped Sangyod rice per 100 g of Krayasart mixture, with other ingredients kept constant. The optimal recipe was subsequently dried in compressed forms (2 × 2 × 2 cm and 2 × 4 × 2 cm; width × length × height) at 60, 80, and 100°C. As the amount of popped Sangyod rice increased, the L* value increased, whereas the a*, b*, and hardness values tended to decrease. Final moisture content decreased as the amount of popped rice increased. The formulation containing 10.5 g of popped Sangyod rice per 100 g of Krayasart received the highest customer satisfaction score. Consequently, formulation 1 (with 10.5 g of popped Sangyod rice per 100 g) was selected for testing in the drying process at 60°C, 80°C, and 100°C. The results indicated that the initial moisture content was 11.51% wb; after drying, it decreased to 7.36-9.34% wb for the 2 x 2 x 2 cm and 8.02-9.52% wb for the 2 x 4 x 2 cm samples. The water activity values in each sample were less than 0.65. Higher drying temperatures increased the a*, b*, and hardness values but decreased the L* value. The highest sensory test scores for both sizes of Krayasart were achieved at a drying temperature of 80°C.

How to Cite

Langkapin, J. ., Parnsakhorn, S., & Oupathumpanont, O. . (2025). Impact of popped sangyod rice on the Physicochemical and Sensory qualities of dried Krayasart bars. Asia-Pacific Journal of Science and Technology, 30(05), APST–30. https://doi.org/10.14456/apst.2025.80

References

Krayasart: food for restoring energy in athletes. Daily Archives. 2012.

Khanom Krayasart. Career Project.Topic: Making Khanom Krayasart. Phothirai Pittayakarn. 2024.

Yang Q, Zhang Z, Gregg E W, Flanders W D, Merritt R, Hu F B. Added sugar intake and cardiovascular diseases mortality among US adults. JAMA internal medicine, 2014; 174(4): 516-524.

Achanupap S. Diabetes. Doctor Chonburi Mag. 2011; 381:1-5.

Abou-Arab AE, Abou-Arab A, Abu-Salem MF. Physico-chemical assessment of natural sweeteners steviosides produced from Stevia rebaudiana bertoni plant. Afr J Food Sci. 2010;4(5): 269-281.

Leardkamolkarn V, Thathana W, Sriprasert P, Srichumpoung S. Nutritional values, antioxidant and phytochemicals in Sangyod rice. RMUTP Res J. 2011;5(2): 215-226.

Wattanakul U, Wattanakul W, Mahae N, Charoonrat P. Harvesting period and shelf life on some nutritional value of pre-germinated sung yod organic brown rice. J Agricult. 2011;27(2):165-174.

Khoo H E, Azlan A, Tang S T, Lim S M. Anthocyanidins and anthocyanins: colored pigments as food, pharmaceutical ingredients, and the potential health benefits. Food Nutr Res. 2017;61(1): 1361-1779.

Bunrat N. Quality of sungyod rice during storage and its instant drink production [Master’s thesis]. Songkhla: Prince of Songkla University; 2016.

Kolawole O F, Joseph C I, Funke A. A. Kinetics of mass transfer and colour changes during osmotic dehydration of watermelon. J Food Eng. 2007;80(3): 979–985.

AOAC. Official methods of analysis of the association of official analytical chemists. (18thed). Gaithersburg, MD: Association of Official Analytical Chemists; 2000.

Mahattanatawee K, Juntarasri K, Sawangphop D. Quick-cooking mixed brown rice. J Food Technol Siam University. 2012; 8(1): 35-46.

Pitija K, Mahatheeranont S, Rayanakorn M. Determination of anthocyanins in pigmented rice by HPLC–DAD and LC–ESI-MS. Food Chemistry. 2013; 141(1): 735–741.

Patras A, Brunton N P, O’Donnell C, Tiwari B K. Effect of thermal processing on anthocyanin stability in foods: Mechanisms and kinetics of degradation. Trends Food Sci Technol. 2010; 21(1):3–11.

Mazza G, Miniati E. Anthocyanins in fruits, vegetables, and grains. 1st Edition: CRC Press.1993;384.

Abdel-Aal E S M, Hucl P. A rapid method for quantifying total anthocyanins in blue aleurone and purple pericarp wheats. Cereal Chemistry. 1999;76(3): 350-354.

Suppavorasatit I, Panworn K, Kiatruangkrai C, Chaiwanichsiri S. Effect of cooking methodson -aminobutyric acid content and physico-chemical properties of germinated brown rice. J Food Technol Siam University. 2014;10(1): 30-41.

Rangsadthong W. Food processing technology. 5th ed. Bangkok: Text J Publ Co Ltd. 2014;5(3):500-502.

Lekjing S, Noonim P, Boottajean S, Chantawong P. Effect of substitution of wheat flour with Sangyod brown rice flour on physicochemical and sensory qualities in snack product. Khon Kaen Agr. J. 2019; 47(1): 679-684.

Zhang Q, Guo L, Li M, Wang L, Chen C, Chen G. Improving drying characteristics and physicochemical quality of Angelica sinensis by novel tray rotation microwave vacuum drying. Foods. 2022;11(6):1202.

Saowapark S, Summawattana T, Artnarong S. Effect of drying temperature on quality of dried garcinia (Garciniaatroviridis). Agricultural Sci J. 2014;45(2): 37-40.

Kaleemullah S, Kailappan R. Modeling of thin-layer drying kinetics of red chillies. J Food Eng. 2006;76(1): 531-537.

Zeng Z, Han C, Wang Q, Yuan H, Zhang X, Li B. Analysis of drying characteristic, effective moisture diffusivity and energy, exergy and environment performance indicators during thin layer drying of tea in a convective-hot air dryer. Foods. 2024;13(4):50-51.

Martins S I F S, Jongen W M F, van Boekel M A J S. A review of Maillard reaction in food and implications to kinetic modeling. Trends Food Sci Technol. 2000; 11(9-10): 364–373.

Lee Y C, Kim J S, Lee H G. Influence of drying temperature on enzyme inactivation and quality attributes of onion powder. Food Chem.2015; 188: 258–263.

Khan M R. Osmotic dehydration technique for fruit preservation-A review. Pakistan J Food Sci. 2012;22(2): 71-85.

Aktas T, Ulger P, Daglioglu F, Hasturk F. Change of nutritional and physical quality characteristics during storage of osmotic pretreated apple before hot air drying and sensory evaluation. J Food Quality.2013;36(6): 411–425.

Ranapanon NR. Food Chemistry. 4th ed. Odean Store Publisher: Bangkok; 2000.

Fellows P. Food Processing Technology Principles and Practice. 2nd ed. Woodhead Publishing Limited. Cambridge; 2000.

Mujumdar A S. Handbook of industrial drying 4th ed. CRC Press; 2014.

Published:

License

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.