Marco Torre

National Research Council of Italy, Institute of Atmospheric Pollution Research (CNR-IIA), Monterotondo, Italy

Patrizio Tratzi

National Research Council of Italy, Institute of Atmospheric Pollution Research (CNR-IIA), Monterotondo, Italy

Ting-Wu Ko

Institute of Green Products, Feng Chia University, Taichung, 407102, Taiwan

Maria Luisa Feo

National Research Council of Italy, Institute of Atmospheric Pollution Research (CNR-IIA), Monterotondo, Italy

Laura Tomassetti

National Research Council of Italy, Institute of Atmospheric Pollution Research (CNR-IIA), Monterotondo, Italy

Cristina Riccucci

National Research Council of Italy, Institute of Nanostructured Materials (CNR-ISMN), Monterotondo, Italy

Gabriella di Carlo

National Research Council of Italy, Institute of Nanostructured Materials (CNR-ISMN), Monterotondo, Italy

Monica Carnevale

Consiglio per la Ricerca in Agricoltura e l’Analisi dell’Economia Agraria, CREA-IT Centro di ricerca Ingegneria e Trasformazioni agroalimentari, Monterotondo, Italy

Francesco Gallucci

Consiglio per la Ricerca in Agricoltura e l’Analisi dell’Economia Agraria, CREA-IT Centro di ricerca Ingegneria e Trasformazioni agroalimentari, Monterotondo, Italy

Chen-Yeon Chu

Master’s Program of Green Energy Science and Technology, Feng Chia University, Taichung, Taiwan

Chen-Hua Hsueh

General Education Center, Feng Chia University, Taichung, 407102, Taiwan

Francesco Petracchini

National Research Council of Italy, Institute of Atmospheric Pollution Research (CNR-IIA), Monterotondo, Italy

Valerio Paolini

National Research Council of Italy, Institute of Atmospheric Pollution Research (CNR-IIA), Monterotondo, Italy

DOI: https://doi.org/10.14456/apst.2025.38

Keywords: Alkaline Biogas production Diaper Microcrystalline cellulose Waste management

Abstract

The introduction of absorbent hygiene products (AHPs) has helped improve the quality of life for people, but AHPs also cause environmental problems; diaper manufacturing, distribution, use, and waste management produce 2.7 Mt of greenhouse gases (GHG) per year. This study measures the biochemical methane potential (BMP) of cellulose recycled from AHPs and aims to evaluate the impact of pre-treatments applied to AHP-derived cellulose on biogas production. The cellulose from AHPs has been divided into four categories with different pre-treatment or no pre-treatment: new cellulose (UC), treated post-consumer cellulose (TC), treated unused cellulose (TU), and cellulose soaked in NaOH, using microcrystalline cellulose (MC) as a benchmark. The measure of biogas production shows that TC resulted in the highest biogas production yield (426.9 mL/g volatile solid (VS)), while cellulose treated with NaOH resulted in the highest methane production yield (309.7 mL/g VS). The results of TC were mostly in line with microcrystalline cellulose.

How to Cite

Torre, M., Tratzi, P., Ko, T.-W., Feo, M. L., Tomassetti, L., Riccucci, C., di Carlo, G., Carnevale, M., Gallucci, F., Chu, C.-Y., Hsueh, C.-H., Petracchini, F., & Paolini, V. (2025). Industrial and Classical Pre-treatment for Enhanced Biomethane Production from Cellulosic Materials in Absorbent Hygiene Products. Asia-Pacific Journal of Science and Technology, 30(03), APST–30. https://doi.org/10.14456/apst.2025.38

References

Mendoza JMF, D’Aponte F, Gualtieri D, et al. Disposable baby diapers: Life cycle costs, eco-efficiency and circular economy. J Clean Prod. 2019;211:455-467.

Arena U, Ardolino F, DiGregorio F. Technological, environmental and social aspects of a recycling process of post-consumer absorbent hygiene products. J Clean Prod. 2016;127:289-301.

Khoo SC, Phang XY, Ng CM, et al. Recent technologies for treatment and recycling of used disposable baby diapers. Process Saf Environ Prot. 2019;123:116-129.

Ghosh P, Thakur IS, Kaushik A. Bioassays for toxicological risk assessment of landfill leachate: A review. Ecotoxicol. Environ Saf. 2017;141:259-270.

Ichiura H, Nakaoka H, Konishi T. Recycling disposable diaper waste pulp after dehydrating the superabsorbent polymer through oxidation using ozone. J Clean Prod. 2020;276:12350.

Somma M, Vaccaro G, Landolfo G. A method and apparatus for separating plastic and cellulose from post-consumer absorbent sanitary products. U S Patent. 2018. p. 20.

Gonzalez-Estrella J, Asato CM, Stone JJ, et al. A review of anaerobic digestion of paper and paper board waste. Rev Environ Sci Biotechnol. 2017;16:569-590.

Paolini V, Petracchini F, Segreto M, et al. Environmental impact of biogas: A short review of current knowledge. J Environ Sci Heal – Part A Toxic/Hazardous Subst Environ Eng. 2018;53:899-906.

Panigrahi S, Sharma HB, Dubey BK. Overcoming yard waste recalcitrance through four different liquid hot water pretreatment techniques – Structural evolution, biogas production and energy balance. Biomass and Bioenergy. 2019;127:105268.

Khan MU, Usman M, Ashraf MA, et al. A review of recent advancements in pretreatment techniques of lignocellulosic materials for biogas production: Opportunities and Limitations. Chem Eng J Adv. 2022;10:100263.

Kobayashi F, Take H, Asada C, et al. Methane production from steam-exploded bamboo. J Biosci Bioeng. 2004;97:426-428.

Steinbach D, Wüst D, Zielonka S, et al. Steam explosion conditions highly influence the biogas yield of rice straw. Molecules. 2019;24:3492.

Poddar BJ, Nakhate SP, Gupta RK, et al. A comprehensive review on the pretreatment of lignocellulosic wastes for improved biogas production by anaerobic digestion. Int J Environ Sci Technol. 2022;19:3429-3456.

Kaparaju P, Luostarinen S, Kalmari E, et al. Co-digestion of energy crops and industrial confectionery by-products with cow manure: batch-scale and farm-scale evaluation. Water Sci Technol. 2002;45:275-280.

Hjorth M, Gränitz K, Adamsen APS, et al. Extrusion as a pretreatment to increase biogas production. Bioresour Technol. 2011;102:4989-4994.

Kupryaniuk K, Oniszczuk T, Combrzyński M, et al. The influence of corn straw extrusion pretreatment parameters on methane fermentation performance. Materials (Basel). 2020;13:3003.

Yu Q, Liu R, Li K, et al. A review of crop straw pretreatment methods for biogas production by anaerobic digestion in China. Renew. Sustain. Energy Rev. 2019;107:51-58.

Linyi C, Yujie Q, Buqing C, et al. Enhancing degradation and biogas production during anaerobic digestion of food waste using alkali pretreatment. Environ Res. 2020;188:109743.

Zhurka M, Spyridonidis A, Vasiliadou IA, et al. Biogas production from sunflower head and stalk residues: Effect of alkaline pretreatment. Molecules. 2020;25:164.

Bittencourt GA, Barreto E da S, Brandão RL, et al. Fractionation of sugarcane bagasse using hydrothermal and advanced oxidative pretreatments for bioethanol and biogas production in lignocellulose biorefineries. Bioresour Technol. 2019;292:121963.

Abraham A, Mathew AK, Park H, et al. Pretreatment strategies for enhanced biogas production from lignocellulosic biomass. Bioresour Technol. 2020;301:122725.

Uellendahl H, Wang G, Møller HB, et al. Energy balance and cost-benefit analysis of biogas production from perennial energy crops pretreated by wet oxidation. Water Sci Technol. 2008;58:1841-1847.

Fox M, Noike T. Wet oxidation pretreatment for the increase in anaerobic biodegradability of newspaper waste. Bioresour Technol. 2004;91:273-281.

Yadav M, Vivekanand V. Combined fungal and bacterial pretreatment of wheat and pearl millet straw for biogas production – A study from batch to continuous stirred tank reactors. Bioresour Technol. 2021;321:124523.

Yuan H, Zhu N. Progress in inhibition mechanisms and process control of intermediates and by-products in sewage sludge anaerobic digestion. Renew Sustain Energy Rev. 2016;58:429-438.

Yunqin L, Dehan W, Lishang W. Biological pretreatment enhances biogas production in the anaerobic digestion of pulp and paper sludge. Waste Manag Res. 2010;9:800-810.

Ma X, Wen G. Development history and synthesis of super-absorbent polymers: a review. J Polym Res. 2020;27:1-12.

Mignon A, DeBelie N, Dubruel P, et al. Superabsorbent polymers: A review on the characteristics and applications of synthetic, polysaccharide-based, semi-synthetic and ‘smart’ derivatives. Eur Polym J. 2019;117:165-178.

Zohuriaan-Mehr MJ, Kabiri K. Superabsorbent polymer materials: A review. Iran Polym J. (English Ed. 2008;17:451-477.

Paolini V, Petracchini F, Carnevale M, et al. Characterisation and cleaning of biogas from sewage sludge for biomethane production. J Environ Manage. 2018;217:288-296.

Mechtcherine V, Wyrzykowski M, Schröfl C, et al. Application of super absorbent polymers (SAP) in concrete construction—update of RILEM state-of-the-art report. Mater Struct Constr. 2021;54:80-99.

Farzanian K, Pimenta Teixeira K, Perdigão Rocha I, et al. The mechanical strength, degree of hydration, and electrical resistivity of cement pastes modified with superabsorbent polymers. Constr Build Mater. 2016;109:156-165.

Siriwatwechakul W, Siramanont J, Vichit-Vadakan W. Behavior of Superabsorbent Polymers in Calcium- and Sodium-Rich Solutions. J Mater Civ Eng. 2012;24:976-980.

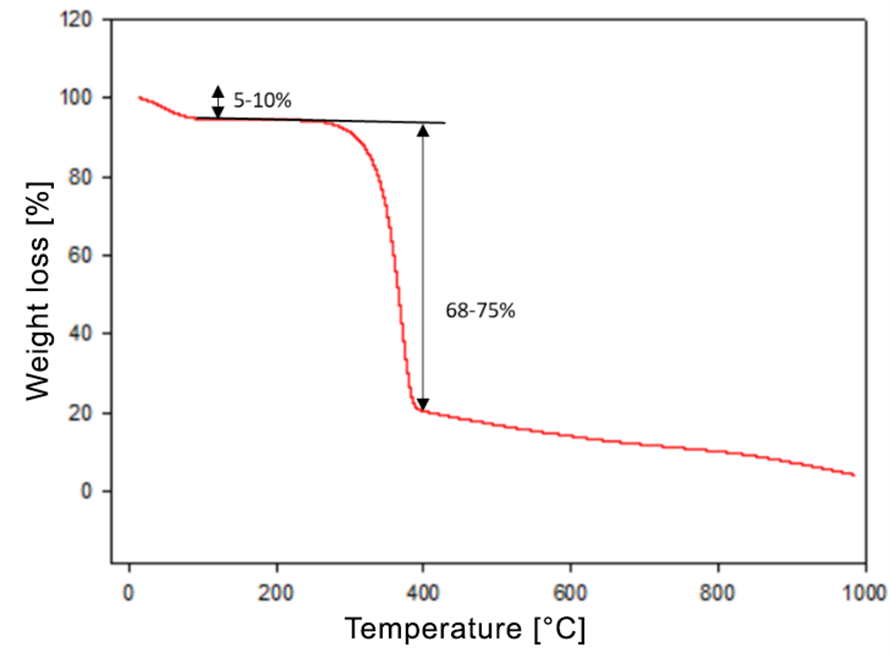

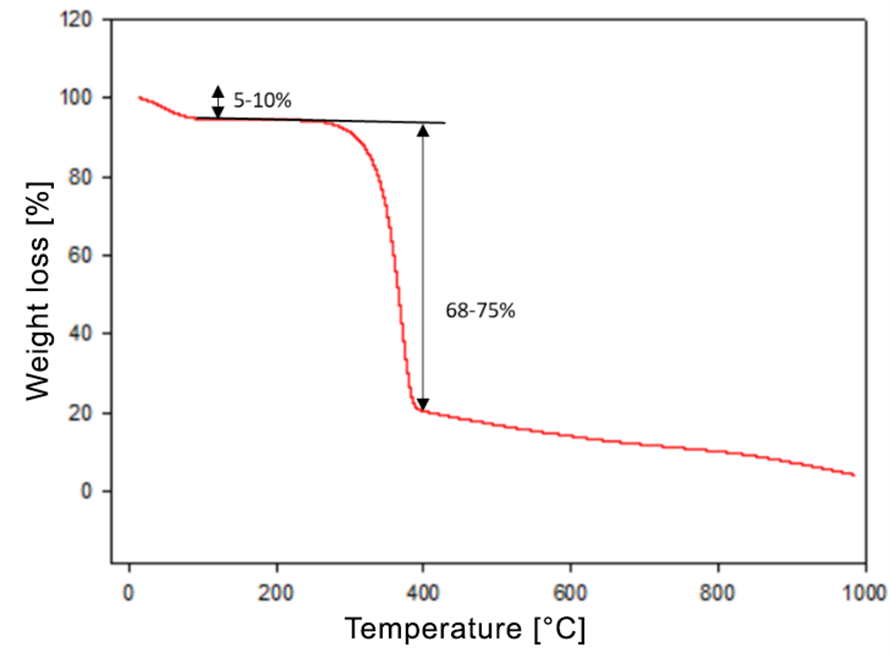

Abidi N, Hequet E, Cabrales L, et al. Evaluating cell wall structure and composition of developing cotton fibers using fourier transform infrared spectroscopy and thermogravimetric analysis. J Appl Polym Sci. 2008;107:476-486.

Espinosa-Valdemar RM, Vázquez-Morillas A, Ojeda-Benítez S, Arango-Escorcia G, Cabrera-Elizalde S, Quecholac-Piña X, Velasco-Pérez M, Sotelo-Navarro PX. Assessment of Gardening Wastes as a Co-Substrate for Diapers Degradation by the Fungus Pleurotus ostreatus. Sustain. 2015;7:6033–6045.

Mateescu C. Influence of the hydrostatic pressure on biogas production in anaerobic digesters. RomBiotechnol Lett. 2017;21:11941-11948.

Published:

License

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.