Raden Faridz

Department of Agroindustrial Technology, University of Trunojoyo, Bangkalan, Indonesia

Raden Arief Firmasyah

Department of Agroindustrial Technology, University of Trunojoyo, Bangkalan, Indonesia

DOI: https://doi.org/10.14456/apst.2025.39

Keywords: Cassava Convective drying Intermittent drying Drying models Energy-saving

Abstract

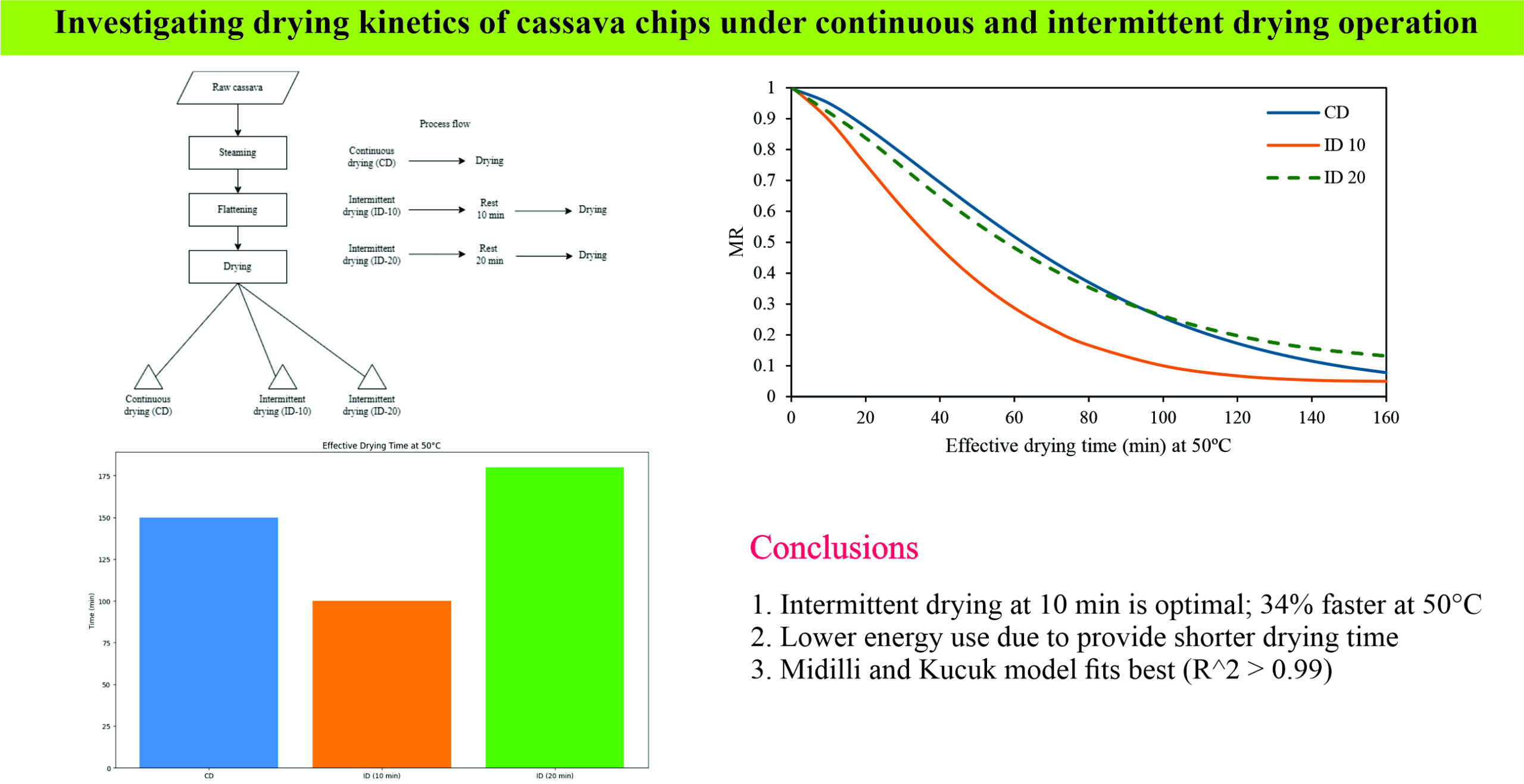

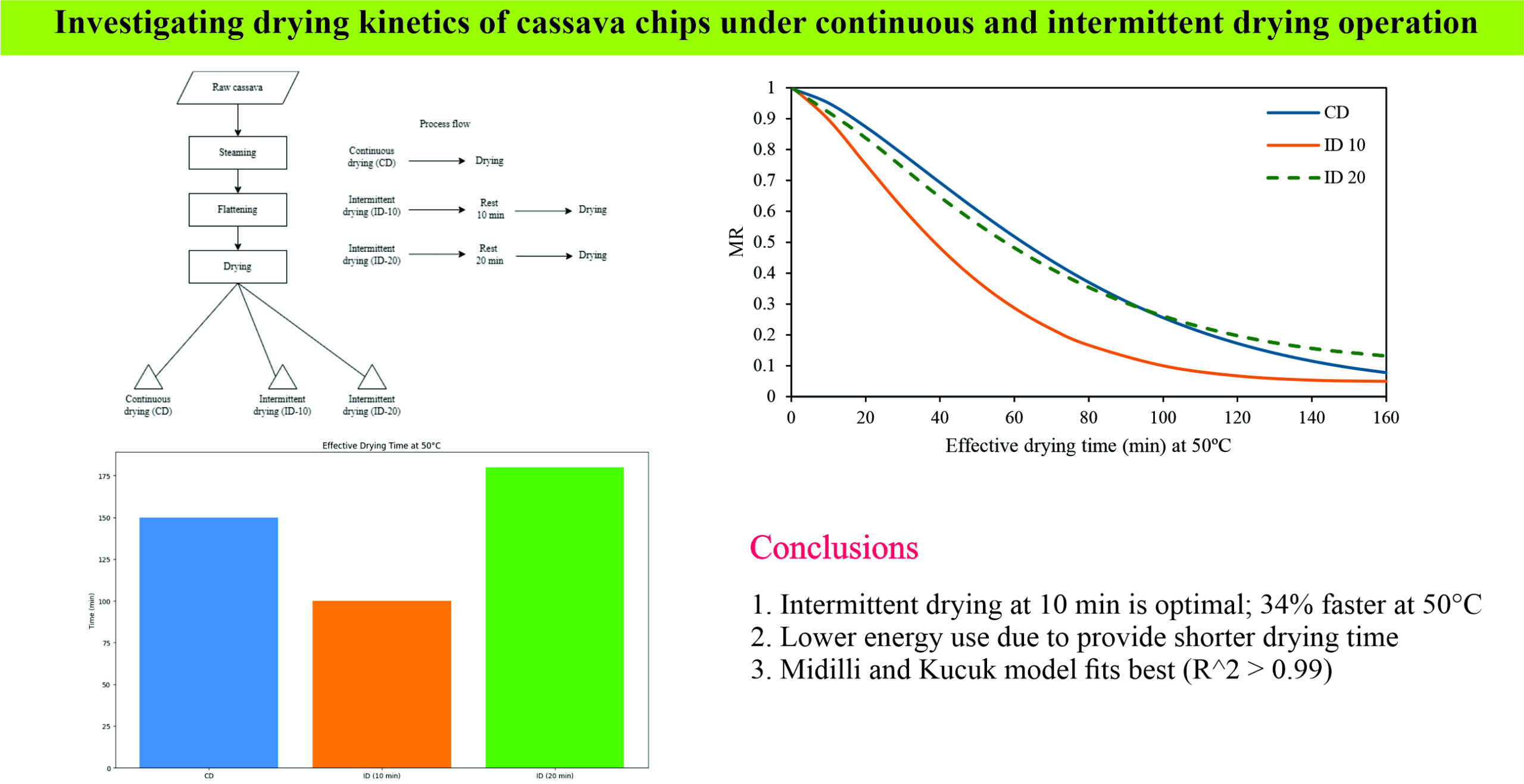

Krepek tette is one of the popular cassava chips, which has become a signature snack from Pamekasan, Indonesia. Several studies have shown that its production process is significantly different from other chips, leading to distinct tastes and textures. One critical step in the process is drying, which largely depends on the open sun drying method. This method has been reported to produce better product quality but causes contamination and consumes more energy. To overcome the challenges, intermittent drying has been introduced as a novel technology that maintains product quality and consumes less energy. Therefore, this study aimed to determine drying kinetics of K. tette based on the thin layer drying model using 2 different methods, continuous and intermittent. Experiments were conducted with continuous and intermittent drying with an oven dryer at 50°C and 60°C. Intermittent drying was conducted by leaving the product out of the oven and placing it in a desiccator. The duration was 10 and 20 min, while the resting time was 20 and 40 min, respectively. The result showed that drying kinetics of K. tette provided a good fitting curve model based on the Midilli and Kucuk model for continuous and intermittent methods. In addition, intermittent drying at a resting time of 10 min provided a shorter effective drying time of 34% compared to the continuous method. The intermittent drying condition also had lower effective moisture diffusivity. These results confirmed that intermittent drying reduced energy consumption by shortening the effective drying time.

How to Cite

Faridz, R. ., & Firmasyah, R. A. (2025). Investigating drying kinetics of cassava chips under continuous and intermittent drying operation . Asia-Pacific Journal of Science and Technology, 30(03), APST–30. https://doi.org/10.14456/apst.2025.39

References

Tamami NDB. Peluang usaha kuliner khas Madura berbahan singkong pada agroindustri Krepek tette di Pamekasan. Agriekonomika. 2013;2(1):40–48.

Tambunan T. Recent evidence of the development of micro, small and medium enterprises in Indonesia. J Glob Entrep Res. 2019 Dec;9(1):18.

Jain D, Pathare PB. Study the drying kinetics of open sun drying of fish. J Food Eng. 2007 Feb;78(4):1315–1319.

Singh P, Vyas S, Yadav A. Experimental comparison of open sun drying and solar drying based on evacuated tube collector. Int J Sustain Energy. 2019;38(4):348–367.

Park HW, Han WY, Yoon WB. Drying characteristics of soybean (Glycine Max) using continuous drying and intermittent drying. Int J Food Eng. 2018;14:9–10.

Cihan A, Kahveci K, Hacihafizoǧlu O. Modelling of intermittent drying of thin layer rough rice. J Food Eng. 2007;79(1):293–298.

Chin SK, Law CL. Product quality and drying characteristics of intermittent heat pump drying of Ganoderma tsugae Murrill. Dry Technol 2010;28(12):1457–1465.

Takougnadi E, Boroze TET, Azouma OY. Development of an intermittent drying process of onion. Cogent Food Agric. 2018;4(1)1422225.

Pereira JCA, da Silva WP, Gomes JP, Queiroz AJ de M, de Figueirêdo RMF, de Melo BA, et al. Continuous and intermittent drying of rough rice: effects on process effective time and effective mass diffusivity. Agriculture (Switzerland). 2020;10(7):1–13.

Filippin AP, Filho LM, Fadel V, Mauro MA. Thermal intermittent drying of apples and its effects on energy consumption. Dry Technol. 2018;36(14):1662–1677.

Kowalski SJ, Pawłowski A. Energy consumption and quality aspect by intermittent drying. Chem Eng Process Process Intensif. 2011;50(4):384–390.

Franco CMR, de Lima AGB, Farias VSO, da Silva WP. Modeling and experimentation of continuous and intermittent drying of rough rice grains. Heat Mass Transf. 2020;56(3):1003-1014.

Brito RC, Zacharias MB, Forti VA, Freire JT. Physical and physiological quality of intermittent soybean seeds drying in the spouted bed. Dry Technol. 2021;39(6):820–833.

Nurafifah F, Luqman Chuah A, Puteri Farah Wahida MA. Drying of Plectranthus amboinicus (lour) spreng leaves by using oven dryer. Eng Agric Environ Food. 2018;11(4):239–244.

Okonkwo UC, Onokwai AO, Okeke CL, Osueke CO, Ezugwu CA, Diarah RS, et al. Investigation of the effect of temperature on the rate of drying moisture and cyanide contents of cassava chips using oven drying process. Int J Mech Eng Technol. 2019;10(1):1507–1520.

Argo BD, Ubaidillah U. Thin-layer drying of cassava chips in multipurpose convective tray dryer: Energy and exergy analyses. J Mech Sci Technol. 2020;34(1):435–442.

Ajala AS, Ngoddy PO, Olajide JO. Implementation of a dualistic model for scale up of a tunnel drying of cassava chips. Agric Eng Int: CIGR J. 2019;21(3):150–158.

Simo-Tagne M, Tagne AT, Ndukwu MC, Bennamoun L, Akong MBO, El Marouani M, et al. Numerical study of the drying of cassava roots chips using an indirect solar dryer in natural convection. AgriEngineering. 2021;3(1):138–157.

Jumah R, Al-Kteimat E, Al-Hamad A, Telfah E. Constant and intermittent drying characteristics of olive cake. Dry Technol. 2007;25(9):1421–1426.

Reza A, Jalaledin S. Study on drying kinetics of paddy rice: Intermittent drying. J Chem Chem Eng. 2016;35(3).

da Silva WP, e Silva CMDPS, Gama FJA, Gomes JP. Mathematical models to describe thin-layer drying and to determine drying rate of whole bananas. J Saudi Soc Agric Sci. 2014;13(1):67–74.

Mewa EA, Okoth MW, Kunyanga CN, Rugiri MN. Experimental evaluation of beef drying kinetics in a solar tunnel dryer. Renew Energy. 2019;139:235–241.

Doymaz I, Tugrul N, Pala M. Drying characteristics of dill and parsley leaves. J Food Eng. 2006;77(3):559–565.

Khanali M, Rafiee S, Jafari A, Hashemabadi SH, Banisharif A. Mathematical modeling of fluidized bed drying of rough rice (Oryza sativa L.) grain. J Agric Technol. 2012;8(3):795–810.

Huang D, Men K, Tang X, Li W, Sherif SA. Microwave intermittent drying characteristics of Camellia oleifera seeds. J Food Process Eng. 2021;44(1) e13608.

Szadzińska J, Mierzwa D, Pawłowski A, Musielak G, Pashminehazar R, Kharaghani A. Ultrasound- and microwave-assisted intermittent drying of red beetroot. Drying Technology. 2020;38(1–2):93–107.

Babalis SJ, Papanicolaou E, Kyriakis N, Belessiotis VG. Evaluation of thin-layer drying models for describing drying kinetics of figs (Ficus carica). J Food Eng. 2006;75(2):205–214.

Gupta S, Cox S, Abu-Ghannam N. Effect of different drying temperatures on the moisture and phytochemical constituents of edible Irish brown seaweed. LWT. 2011;44(5):1266–1272.

Salarikia A, Miraei Ashtiani SH, Golzarian MR. Comparison of drying characteristics and quality of peppermint leaves using different drying methods. J Food Process Preserv. 2017;41(3) e12930.

Tello-Ireland C, Lemus-Mondaca R, Vega-Gálvez A, López J, Di Scala K. Influence of hot-air temperature on drying kinetics, functional properties, colour, phycobiliproteins, antioxidant capacity, texture and agar yield of alga Gracilaria chilensis. LWT. 2011;44(10):2112–2118.

Manikantan MR, Barnwal P, Goyal RK. Drying characteristics of paddy in an integrated dryer. J Food Sci Technol. 2014 Apr 1;51(4):813–819.

Dehghannya J, Kadkhodaei S, Heshmati MK, Ghanbarzadeh B. Ultrasound-assisted intensification of a hybrid intermittent microwave – hot air drying process of potato: Quality aspects and energy consumption. Ultrasonics. 2019;96:104–122.

Motevali A, Minaei S, Banakar A, Ghobadian B, Khoshtaghaza MH. Comparison of energy parameters in various dryers. Energy Convers Manag. 2014;87:711–725.

Mishra L, Hauchhum L, Gupta R. Development and performance investigation of a novel solar-biomass hybrid dryer. Appl Therm Eng. 2022;211:118492.

Ben Mustapha N, Boumnijel I, Mihoubi D. Tempering drying and energy consumption. J Heat Transfer. 2022;144(10):102103.

Kowalski SJ, Pawłowski A. Modeling of kinetics in stationary and intermittent drying. Dry Technol. 2010;28(8):1023–1031.

Yang Z, Zhu E, Zhu Z, Wang J, Li S. A comparative study on intermittent heat pump drying process of Chinese cabbage (Brassica campestris L.ssp) seeds. Food Bioprod Process. 2013;91(4):381–388.

Kumar C, Karim MA, Joardder MUH. Intermittent drying of food products: A critical review. J Food Eng. 2014;121;48–57.

Wang Q, Li S, Han X, Ni Y, Zhao D, Hao J. Quality evaluation and drying kinetics of shitake mushrooms dried by hot air, infrared and intermittent microwave–assisted drying methods. LWT. 2019;107:236–242.

Wang Y, Li X, Chen X, Li B, Mao X, Miao J, et al. Effects of hot air and microwave-assisted drying on drying kinetics, physicochemical properties, and energy consumption of chrysanthemum. Chem Eng Process – Process Intensification. 2018;129:84–94.

Zogzas NP, Maroulis ZB, Marinos-Kouris D. Moisture diffusivity data compilation in foodstuffs. Dry Technol. 1996;14(10):2225–2253.

Baini R, Langrish TAG. An assessment of the mechanisms for diffusion in the drying of bananas. J Food Eng. 2008;85(2):201–214.

Khan MIH, Kumar C, Joardder MUH, Karim MA. Determination of appropriate effective diffusivity for different food materials. Dry Technol. 2017;35(3):335–346.

Published:

License

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.