Arawan Chanpahol

Program in Industrial Engineering Technology and Logistics, Faculty of Agricultural and Industrial Technology, Phetchabun Rajabhat University, Thailand 67000

Saksirichai Srisawat

Program in Industrial Engineering Technology and Logistics, Faculty of Agricultural and Industrial Technology, Phetchabun Rajabhat University, Thailand 67000

Boonsin Nadondu

Program in Industrial Engineering Technology and Logistics, Faculty of Agricultural and Industrial Technology, Phetchabun Rajabhat University, Thailand 67000

Thongchai Khrueaphue

Program in Industrial Engineering Technology and Logistics, Faculty of Agricultural and Industrial Technology, Phetchabun Rajabhat University, Thailand 67000

Parinyawatr Dhinnabutra

Program of Welding Engineering, Faculty of Technical Education, Rajamangala University of Technology Isan, Khon Kaen, Thailand 40000

Keywords: Underwater welding Hydrogen Carbon steel UW-1 electrode E6013 electrode

Abstract

This article has been retracted by the Editors of the Asia-Pacific Journal of Science and Technology. Following a complaint from a cited author, investigation revealed that 13 out of 31 references (42%) could not be verified in academic databases or scholarly repositories. When asked to verify these citations, the authors provided alternative references, which does not address the fact that the originally cited references do not exist.

The inclusion of fabricated references raises concerns about the validity of the findings and interpretations presented in this work. Consequently, this article represents research misconduct in scholarly publishing. The APST editorial team extends its apologies to the readership for failing to identify this issue during manuscript evaluation and peer review. We are actively strengthening our editorial procedures to ensure similar incidents do not occur going forward.

How to Cite

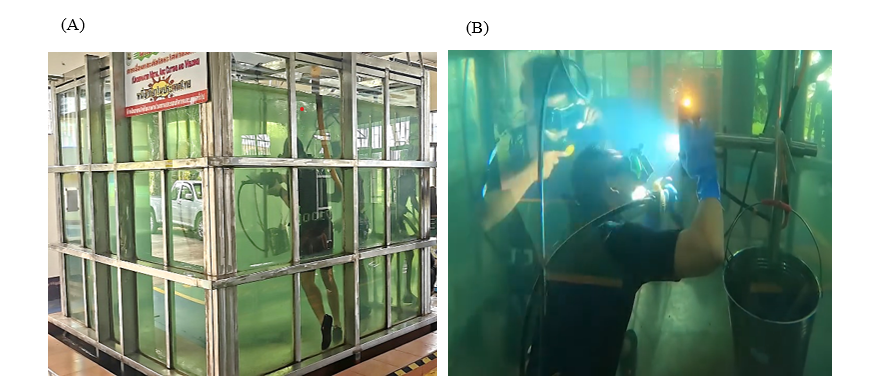

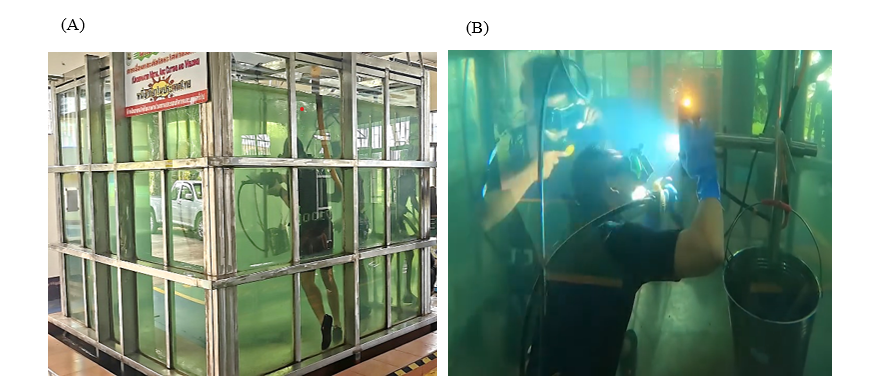

Chanpahol, A. ., Srisawat, S. ., Nadondu, B. ., Khrueaphue, T., & Dhinnabutra, P. . (2025). Investigation of the metallurgical microstructure resulting from underwater welding at depths of 3 and 5 meters using UW-1 and E6013 welding electrodes. Asia-Pacific Journal of Science and Technology, 30(06), APST–30. https://doi.org/10.14456/apst.2025.98

References

Klett J, Hassel T. Effect of water depth on hydrogen content in SMAW wet welded joints. SN Appl Sci. 2020;2:1269.

Verma K, Kumar H. Underwater welding: recent trends and future scope. Int J Emerg Technol. 2012;3(2):115-120.

Sundarapandiyan C, Balamurugan A, Mohan M. A review on underwater welding process. Int J Innov Eng Technol. 2017;8(1):260-265.

Liu L, Wang W, Wang S, Liu J, Feng J. Study on hydrogen-induced cracking in underwater wet welding. J Mater Process Technol. 2015;221:132-139.

Szczucka-Lasota B, Rogalski G, Szymczak C. Characteristics of wet welding with regard to the formation of defects. Arch Metall Mater. 2011;56(3):721-728.

Golikov N, Rogalski G. Effect of environmental conditions on diffusible hydrogen content during underwater wet welding. Weld Int. 2016;30(6):446-452.

Yousefi M, Ghaini FM. Influence of electrode angle and welding polarity on the quality of underwater welds. J Manuf Process. 2019;45:587-595.

Alajmi EF, Alqenaei AA. Underwater welding techniques. J Eng Res Appl. 2017;7(2):14-17.

Joshi MC, Rautela DS, Chauhan R, Suyal S. Scrutinize research on underwater welding process: a review. J Mech Civ Eng. 2016;13(5):74-78.

American Welding Society. Specification for carbon steel electrodes for shielded metal arc welding. 14th Edition. Miami (FL): AWS A5.1/A5.1M. 2012.

Kobayashi Y, Suga Y. Study on performance of new underwater welding electrode UW-1. Q J Jpn Weld Soc. 2011;29(1):63-67.

Dutta Majumdar J. Underwater welding: present status and future scope. J Naval Archit Mar Eng. 2014;3:39-48.

Ersoy E. Recent trends and development of underwater welding. Int J Eng Sci Appl. 2020;4(1):36-44.

Yousef MM, Mohamed MM, Abou-Bakr MH. Estimation of heat input and weld bead characteristics in SMAW. J Mater Process Technol. 2015;222:174-182.

Kim J, Lee S, Kim Y. Heat loss characteristics in underwater welding environments. J Mar Eng Technol. 2019;18(4):203-210.

Nakacho K, Matsumoto T, Tamura Y. Development of advanced electrodes for wet welding and its thermal behavior. Weld Int. 2021;35(12):935-943.

Wang J. Characterization of the underwater welding arc bubble through a visual sensing method. J Mater Process Technol. 2018;251:95-108.

Hikmatullah C. Environment effect on underwater wet welding process of API 5L X65 steel by coating resin-based E6013 electrode. J Trans Syst Eng. 2023;1(1):31-39.

Çolak Z, Ayan Y, Kahraman N. Weld morphology and mechanical performance of marine structural steel welded underwater in a real marine environment. Int J Adv Manuf Technol. 2020;109:491-501.

Vashishtha P. Problems encountered in underwater welding and remedies: a review. Innov Technol Mech Eng. 2022;64(3):1433-1439.

Li H. Microstructure and mechanical properties of underwater wet welded high-carbon-equivalent steel Q460 using austenitic consumables. J Mater Process Technol. 2017;249:149-157.

Klett J, Hassel T. Reducing the risk of hydrogen-induced cold cracks in hyperbaric wet welding of high-strength steels by using austenitic welding consumables. Int J Hydrogen Energy. 2020;45(19):54-60.

Tomków J, Fydrych D, Łabanowski J, Rogalski G. Effect of water depth on the structure and hardness of wet welded joints. Arch Civ Mech Eng. 2019;19(4):1233-1243.

Dariusz F, Rogalski G. Effect of shielded-electrode wet welding conditions on diffusion hydrogen content in deposited metal. Weld Int. 2011;25(3):166-171.

Sezgin B. Hydrogen energy systems for underwater applications. Int J Hydrogen Energy. 2022;47(45):19780-19796.

Nakpradit T, Poopat B. Investigation of diffusible hydrogen content and microstructure examination of underwater welding. Asia Pac J Sci Technol. 2010;3(3):45-51.

Santos VR. Prediction of hydrogen cracking in the wet welding of structural steels with ferritic stick electrodes down to 20 m. J Mater Res Technol. 2021;15:5787-5802.

Basha S, Reddy GM. Effect of welding technique on weld bead characteristics and hydrogen diffusion in wet welding. J Manuf Process. 2014;16(1):113-121.

Kovac M, Krajnik P, Dolšak B. Cost-benefit analysis of welding processes in offshore applications. J Manuf Sci Eng. 2020;142(5):051011.

Shamsudin M, Mohd A, Sulaiman S. Performance of underwater welding electrodes under varying depth conditions. Int J Offshore Polar Eng. 2019;29(2):114-121.

Kumar A, Dwivedi DK. Effect of moisture content in welding electrodes on the mechanical properties of weld metal. Mater Des. 2014;54:702-709.

Published: Nov 5, 2025

License

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.