Nguyen N Thanh

Department of Microbial Biotechnology, Institute of Food and Biotechnology, Can Tho University, Can Tho City 90000, Viet Nam

https://orcid.org/0000-0002-3079-1259

Tran H Duyen

Department of Microbial Biotechnology, Institute of Food and Biotechnology, Can Tho University, Can Tho City 90000, Viet Nam

Nguyen N H Binh

Department of Microbial Biotechnology, Institute of Food and Biotechnology, Can Tho University, Can Tho City 90000, Viet Nam

Luu M Chau

Department of Microbial Biotechnology, Institute of Food and Biotechnology, Can Tho University, Can Tho City 90000, Viet Nam

https://orcid.org/0009-0002-8411-2562

Le Q Viet

Department of Microbial Biotechnology, Institute of Food and Biotechnology, Can Tho University, Can Tho City 90000, Viet Nam

https://orcid.org/0009-0006-1521-3676

Bui H D Long

Department of Microbial Biotechnology, Institute of Food and Biotechnology, Can Tho University, Can Tho City 90000, Viet Nam

https://orcid.org/0000-0003-0926-9033

Warayutt Pilap

Walairukhavej Botanical Research Institute, Mahasarakham University, Maha Sarakham 44150, Thailand

Sudarat Thanonkeo

Walairukhavej Botanical Research Institute, Mahasarakham University, Maha Sarakham 44150, Thailand

Pornthap Thanonkeo

Department of Biotechnology, Faculty of Technology, Khon Kaen University, Khon Kaen 40002, Thailand

https://orcid.org/0000-0003-0842-9760

Huynh X Phong

Department of Microbial Biotechnology, Institute of Food and Biotechnology, Can Tho University, Can Tho City 90000, Viet Nam

Keywords: γ-aminobutyric acid Central Composite Design Fermented pork Lactiplantibacillus plantarum Nem chua

Abstract

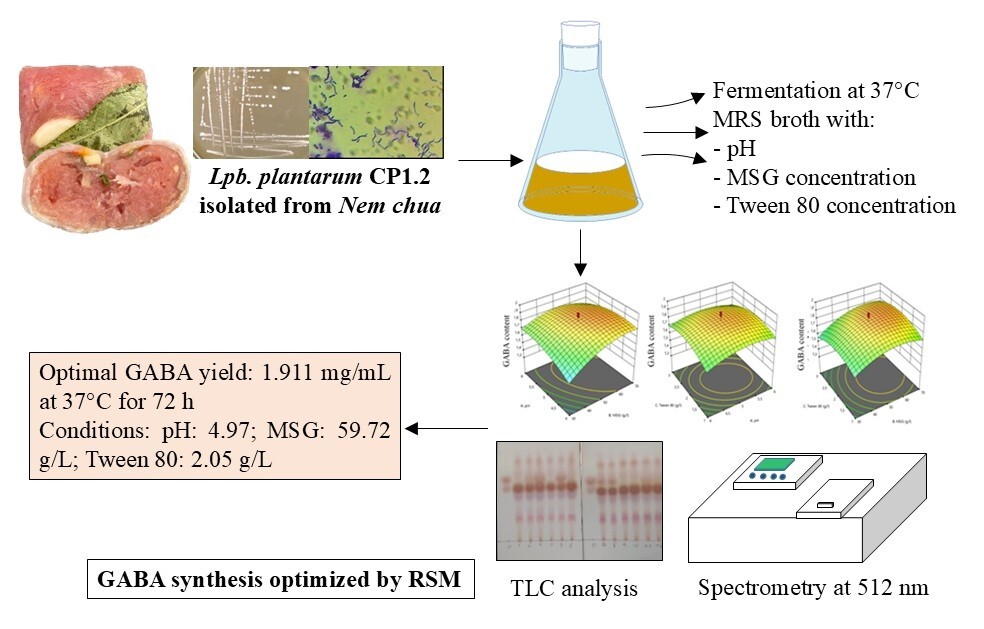

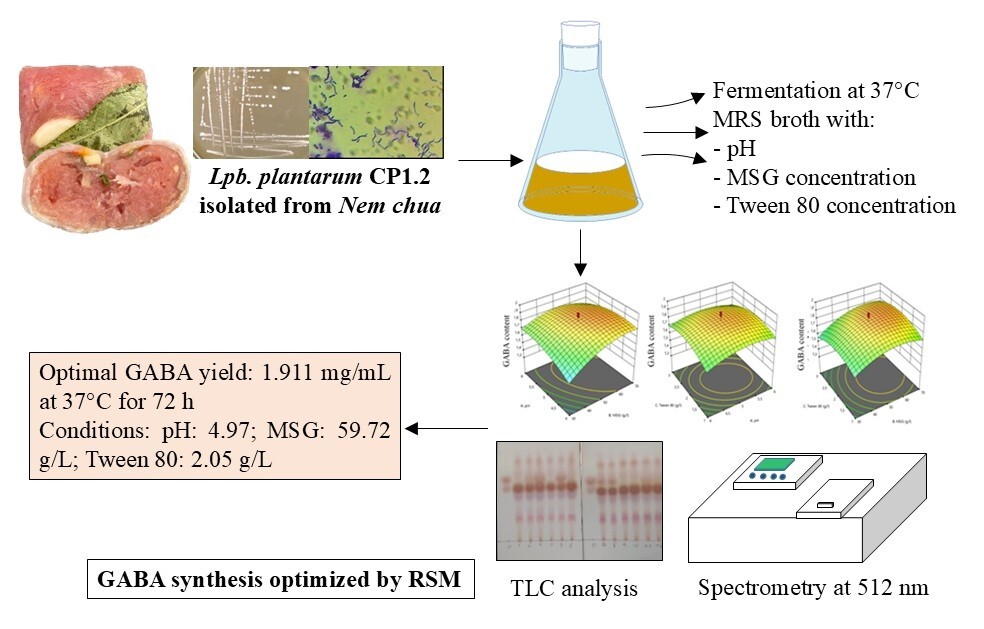

Lactic acid bacteria (LAB) capable of biosynthesizing gamma-aminobutyric acid (GABA) have attracted increasing interest due to their status as safe microorganisms in food preservation and processing. In this study, GABA content was quantified using thin-layer chromatography (TLC), and optimal fermentation conditions, including initial concentrations of monosodium glutamate (MSG), Tween 80, and pH, were modeled using response surface methodology (RSM). The results indicated that Lactiplantibacillus plantarum can produce GABA at a concentration of 1.533 mg/mL after 72 h of fermentation at 37ºC in de Man, Rogosa, and Sharpe (MRS) broth supplemented with 1% MSG at pH 5.0. RSM analysis using central composite design (CCD) demonstrated that the maximum GABA production of 1.911 mg/mL was achieved in an optimized MRS medium with an initial pH of 4.97, supplemented with 59.72 g/L of MSG and 2.05 g/L of Tween 80.

How to Cite

Thanh, N. N. ., Duyen, T. H. ., Binh, N. N. H. ., Chau, L. M. ., Viet, L. Q. ., Long, B. H. D. ., Pilap, W. ., Thanonkeo, S. ., Thanonkeo, P. ., & Phong, H. X. . (2026). Optimization of γ-aminobutyric acid production by Lactiplantibacillus plantarum isolated from Vietnamese fermented pork (nem chua) using central composite design. Asia-Pacific Journal of Science and Technology, 31(01), APST–31. https://doi.org/10.14456/apst.2026.15

References

Sarasa SB, Ramasamy M, Gayathri M, Bency T, Femil SDR, Jayaraman A. A brief review on the non-protein amino acid, gamma-amino butyric acid (GABA): Its production and role in microbes. Curr Microbiol. 2020;77(4):534-544.

Łątka K, Jończyk J, Bajda M. γ-Aminobutyric acid transporters as relevant biological target: Their function, structure, inhibitors and role in the therapy of different diseases. Int J Biol Macromol. 2020;158:750-772.

Watanabe M, Maemura K, Kanbara K, Tamayama T, Hayasaki H. GABA and GABA receptors in the central nervous system and other organs. Int Rev Cytolo. 2002;213:1-47.

Cui Y, Miao K, Niyaphorn S, Qu X. Production of gamma-aminobutyric acid from lactic acid bacteria: A systematic review. Inter J Mol Sci. 2020;21(3):995-998.

Jannoey P, Niamsup H, Lumyong S, Suzuki T, Katayama T, Chairote G. Comparison of gamma-aminobutyric acid production in Thai rice grains. World J Microbiol Biotechnol. 2010;26(2):257-263.

Zheng J, Wittouck S, Salvetti E, Franz MAPC, Harris MBH, Mattarelli P, O’Toole WP, Pot B, Vandamme P, Walter J, Watanabe K, Wuyts S, Felis EG, Gänzle GM, Lebeer S. A taxonomic note on the genus Lactobacillus: Description of 23 novel genera, emended description of the genus Lactobacillus Beijerinck 1901, and union of Lactobacillaceae and Leuconostocaceae. Int J Syst Evol Microbiol. 2020;70(4):2782-2858.

Teixeira JS, Seeras A, Sanchez-Maldonado AF, Zhang C, Su MSW, Gänzle MG. Glutamine, glutamate, and arginine-based acid resistance in Lactobacillus reuteri. Food Microbiol. 2014;42:172-180.

Koh JH, Choi SH, Park SW, Choi NJ, Kim Y, Kim SH. Synbiotic impact of tagatose on viability of Lactobacillus rhamnosus strain GG mediated by the phosphotransferase system (PTS). Food Microbiol. 2013;36(1):7-13.

Loo JS, Oslan SNH, Mokshin NAS, Othman R, Amin Z, Dejtisakdi W, Prihanto AA, Tan JS. Comprehensive review of strategies for lactic acid bacteria production and metabolite enhancement in probiotic cultures: Multifunctional applications in functional foods. Fermentation. 2025;11(5):241-245.

Ayivi RD, Gyawali R, Krastanov A, Aljaloud SO, Worku M, Tahergorabi R, da Silva RC, Ibrahim SA. Lactic acid bacteria: Food safety and human health applications. Dairy. 2020;1(3):202-232.

Anh NL. Health-promoting microbes in traditional Vietnamese fermented foods: A review. Food Sci Hum Wellness. 2015;4(4):147-161.

Nguyen DTL, Van Hoorde K, Cnockarert M, De Brandt E, De Bruyne K, Le BT, Vandamme P. A culture-dependent and-independent approach for the identification of lactic acid bacteria associated with the production of nem chua, a Vietnamese fermented meat product. Food Res Int. 2013;50(1):232-240.

Icer MA, Sarikaya B, Kocyigit E, Atabilen B, Çelik MN, Capasso R, Ağagündüz D, Budán F. Contributions of gamma-aminobutyric acid (GABA) produced by lactic acid bacteria on food quality and human health: current applications and future prospects. Foods. 2024;13(15):2437.

Zhang Q, Zeng L, Tan X, Tang J, Xiang W. An efficient γ-aminobutyric acid (GABA) producing and nitrite reducing ability of Lactobacillus plantarum BC114 isolated from Chinese Paocai. Food Sci Technol Res. 2017;23(5):749-755.

Lin Q, Li D, Qin H. Molecular cloning, expression, and immobilization of glutamate decarboxylase from Lactobacillus fermentum YS2. Electron J Biotechnol. 2017;27:8-13.

Zhuang K, Jiang Y, Feng X, Li L, Dang F, Zhang W, Man C. Transcriptomic response to GABA-producing Lactobacillus plantarum CGMCC 1.2437 T induced by L-MSG. PloS One. 2018;13(6) :e0199021.

Phong, HX, Viet LQ, Chau LM, Long BHD, Thanh NN, Phat DT, Truong LD. Isolation and selection of lactic acid bacteria with the capacity of producing γ-aminobutyric acid (GABA) and antimicrobial activity: Its application in fermented meat product. Curr Nutr Food Sci. 2023;19(8):831-837.

Qiu T, Li H, Cao Y. Pre-staining thin layer chromatography method for amino acid detection. Afri J Biotechnol. 2020;9(5):8679-8681.

Li H, Qiu T, Cao Y, Yang J, Huang Z. Pre-staining paper chromatography method for quantification of γ-aminobutyric acid. J Chromatogr A. 2009;1216(25):5057-5060.

Di Cagno R, Mazzacane F, Rizzello CG, De Angelis M, Giuliani G, Meloni M, De Servi B, Gobbetti M. Synthesis of γ-aminobutyric acid (GABA) by Lactobacillus plantarum DSM19463: Functional grape must beverage and dermatological applications. Appl Microbiol Biotechnol. 2020;86(2):731-741.

Yogeswara IBA., Maneerat S, Haltrich D. Glutamate decarboxylase from lactic acid bacteria – A key enzyme in GABA synthesis. Microorganisms. 2020;8(12):1923.

Ueno Y, Hayakawa K, Takahashi S, Oda K. Purification and characterization of glutamate decarboxylase from Lactobacillus brevis IFO 12005. Biosci Biotechnol Biochem. 1997;61(7):1168-1171.

Dhakal R, Bajpai VK, Baek KH. Production of GABA (γ-aminobutyric acid) by microorganisms: A review. Braz J Microbiol. 2012;43:1230-1241.

Cai H. L X, Li D, Liu W, Han Y, Xu X, Yang P, Meng K. Optimization of gamma-aminobutyric acid production by Lactiplantibacillus plantarum FRT7 from Chinese Paocai. Foods. 2023;12(16):3034.

Tajabadi N, Ebrahimpour A, Baradaran A, Rahim RA, Mahyudin NA, Manap MYA, Bakar FA, Saari N. Optimization of γ-aminobutyric acid production by Lactobacillus plantarum Taj-Apis362 from honeybees. Molecules. 2015;20(4):6654-6669.

Harnentis H, Nurmiati N, Marlida Y, Adzitey F, Huda N. γ-Aminobutyric acid production by selected lactic acid bacteria isolate of an Indonesian indigenous fermented buffalo milk (dadih) origin. Vet World. 2019;12(8):1352.

Diez-Gutiérrez L, Vicente LS, Sáenz J, Esquivel A, Barron LJR, Chávarri M. Biosynthesis of gamma-aminobutyric acid by Lactiplantibacillus plantarum K16 as an alternative to revalue agri-food by-products. Sci Rep. 2022;12(1):18904.

Tanamool V, Hongsachart P, Soemphol W. Screening and characterisation of gamma-aminobutyric acid (GABA) producing lactic acid bacteria isolated from Thai fermented fish (Plaa-som) in Nong Khai and its application in Thai fermented vegetables (Som-pak). Food Sci Technol. 2019;40(2):483-490.

Published: Jan 19, 2026

License

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.